David Buck

VP Sales, Litmus

Crucial for capturing business value from data for driving real-time decisions. Success requires more than unlocking data; it needs effective centralized management and scalability across all plants in the organization.

Overcoming the Hurdles of Legacy Systems in Global Supply Chains

Intermodal transportation hubs, essential to sustaining the flow of international trade, struggle with the real-time tracking of container movements. The reliance on outdated infrastructure, a complex web of systems from multiple stakeholders, and inconsistent data streams lead to diminished visibility into container whereabouts and conditions. This opacity impedes efficiency and complicates the management of resources.

At the heart of all operations lie an array of vital equipment like Ship-to-Shore (STS) and Rubber-Tired Gantry (RTG) cranes, Reach Stackers, Straddle Carriers, and Forklifts. A diverse collection of Programmable Logic Controllers (PLCs), such as Siemens S7-400, Rockwell Automation ControlLogix, Mitsubishi Electric automation systems, among others orchestrate these machines. The aggregate data harvested from these PLCs encompasses not only equipment-specific metrics such as spreader lock/unlock occurrences, trolley and hoist position data, and container dimensions but also includes usage statistics and operational status information from the full suite of handling equipment. Collectively, this data is critical for achieving a comprehensive understanding of equipment performance within the intermodal transportation ecosystem. Effective management of these activities demands instantaneous access to data and existing monitoring systems, burdened by their inability to combine data from diverse sources and constrained by antiquated infrastructure without data capture capabilities, are inadequate.

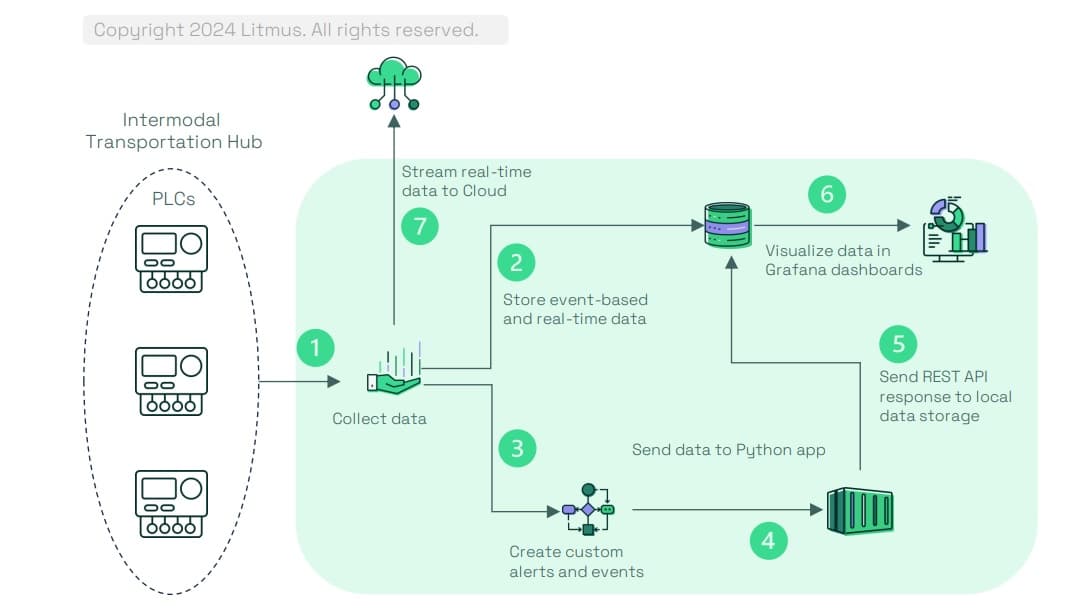

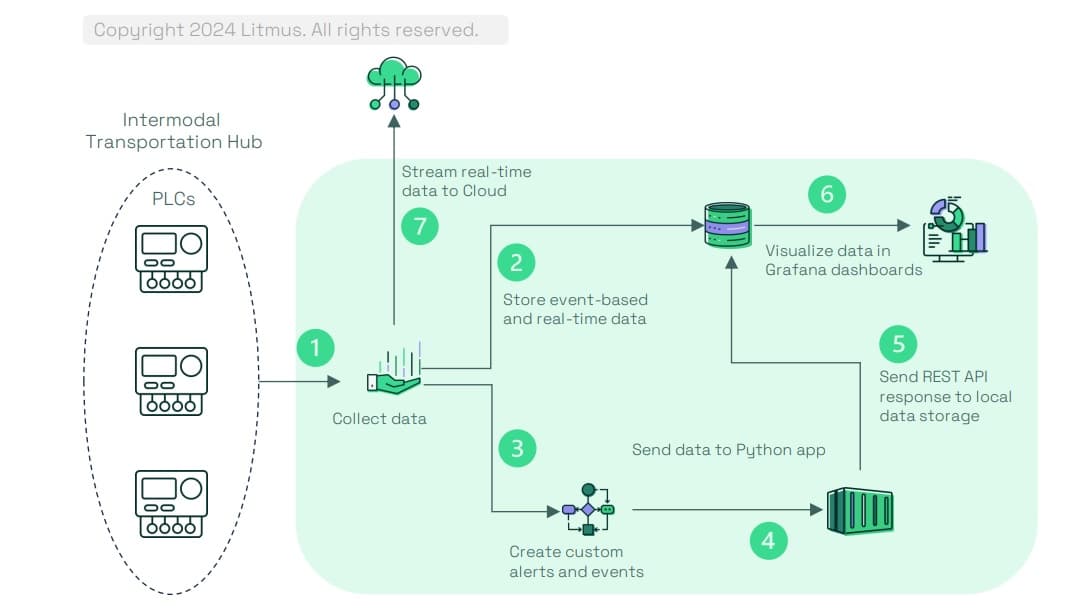

The solution uses the following Litmus Edge features:

Device Hub

Data Hub

Flows Manager (trigger alerts and events).

Applications Marketplace

Local Data Storage

Data Visualization on Grafana Dashboards

Native Bidirectional Cloud Integration

1. Native industrial connectors in the Device Hub collects data using tags in real-time from the equipment PLCs. Some of these tags include:

Spreader lock and unlock events.

Precise trolley and hoist position with precise position.

Container size

Equipment usage details

Miscellaneous data points

2. The collected data is now part of the Data Hub. Litmus Edge provides built-in 7 days local storage and supports data storage in external databases such as Influx DB.

3. Flows manager is used to create custom alerts and events to track activities such as Spreader lock and unlock events.

4. This data is sent via REST APIs to a custom Python application that is running in the Litmus Edge Applications Marketplace. This application uses the collected data to provide critical insights such as:

Cycle Time: The time required for a container loading or unloading operation.

Wait Time: The idle period between crane operations.

Operation Side: Whether the activity is on the shipside or yard side.

5. The Python application sends this data to the local storage.

6. A built-in Grafana container is used to build custom dashboards for real-time data visualization using the data from the local storage.

7. All relevant data points collected from the PLCs are streamed in real-time to the Cloud using native Litmus Edge to Cloud integrations.

Real-time Visibility: Gain a clear picture of equipment activity and container location, improving operational efficiency and resource allocation.

Legacy System Integration: Litmus Edge seamlessly connects with existing PLC systems, eliminating the need for costly infrastructure upgrades.

Unified Data Platform: Creates a single source of truth by consolidating data from disparate sources, leading to better decision-making.

Actionable Insights: Real-time data visualization empowers operators to identify bottlenecks and optimize workflows.

Scalability: The solution can easily scale to accommodate additional locations, cranes, and data sources as the hub grows.

Talk to our experts to find out how Litmus Edge can transform OT data into a strategic asset.

Suranjeeta Choudhury

Director Product Marketing and Industry Relations

Suranjeeta Choudhury heads Product Marketing and Analysts Relations at Litmus.

David Buck

VP Sales, Litmus

Crucial for capturing business value from data for driving real-time decisions. Success requires more than unlocking data; it needs effective centralized management and scalability across all plants in the organization.

Dave McMorran

Director of Sales Engineering

A large manufacturing company created an automated work order based on live monitoring of asset conditions, powered by Litmus Edge – in just a single day.

Suranjeeta Choudhury

Director of Product Marketing

A leading automotive Tier-1 supplier not only improved overall quality control, but also operationalized ML, significantly improving quality inspection speed and accuracy. All of these while freeing up IT for enterprise-wide business-critical initiatives.