Google Cloud + Litmus

Manufacturing Connect: The factory-to-cloud solution for AI-driven manufacturing

The new Google Cloud and Litmus solution for Smart Manufacturing is the most complete factory-to-cloud solution in the world. We’re unifying Google Cloud for AI and analytics with Litmus for factory data connectivity and edge computing to power AI-driven operations.

Google Cloud and Litmus — the perfect factory-to-cloud solution for Smart Manufacturing

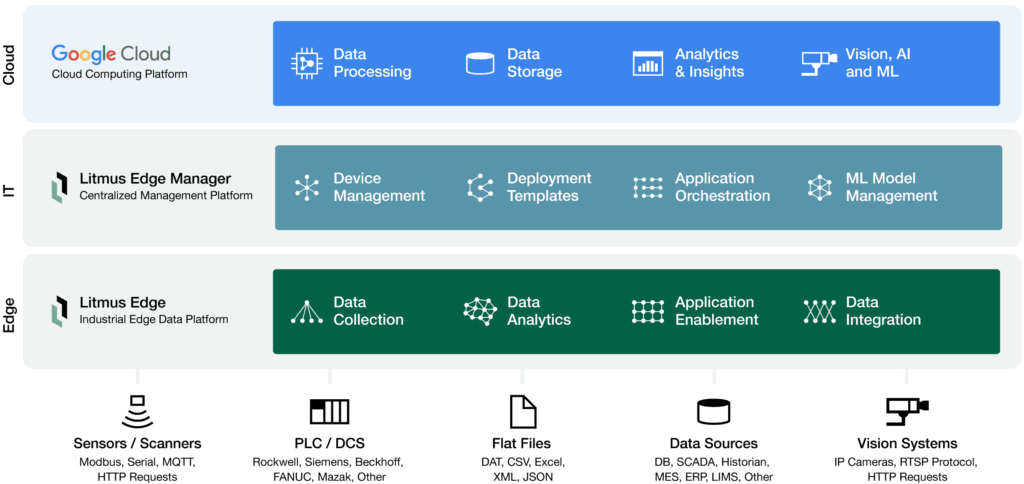

Google Cloud and Litmus combine best-of-breed cloud and edge technologies in an easy-to-use platform for Smart Manufacturing. Google Manufacturing Connect Edge connects to all factory devices, structures and stores the data locally, and performs edge analytics to improve manufacturing operations. The platform sends AI-ready factory data to Google Cloud for advanced analytics that make it easy for manufacturing engineers to enable anomaly detection, predictive maintenance and AI. As organizations scale-out, Google Manufacturing Connect offers enterprise features such as the ability to manage devices across multiple sites, create and share deployment templates, and orchestrate applications and ML models from a single-point-of-control. Explore All Features

Google Cloud and Litmus Manufacturing Solution

Rapid factory connectivity and edge computing meets easy-to-use cloud AI and analytics

The Google Cloud and Litmus solution is comprised of two parts designed to transform manufacturing companies into data-driven factories – Manufacturing Connect at the edge and Manufacturing Data Engine in the cloud. Manufacturing Connect, powered by Litmus, collects and sends contextualized data to Manufacturing Data Engine where it is turned into actionable insights, analytics and AI.

- Complete and easy-to-use factory data connectivity

- Seamless and secure data integration between factory and cloud

- Powers advanced use cases to improve manufacturing operations

- Centralized management and single-point-of-control for large-scale deployments

Manufacturing Connect Edge

Complete on-premise factory data platform with seamless integration to Google Cloud

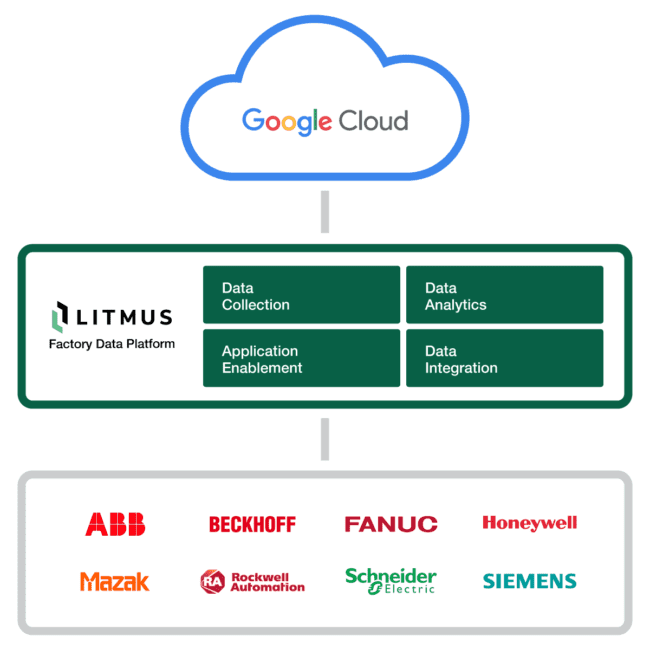

Manufacturing Connect Edge is an enterprise-grade edge data platform, unifying data collection, data analytics, application enablement and data integration to Google Cloud. Deployed as an edge computing platform, the platform provides analytics and KPIs, custom dashboards, and the ability to run any application on the factory floor. Using Docker container technology – Google Cloud machine learning models can be deployed and run at the edge for closed-loop AI.

- Connect to any factory devices with 250+ pre-built drivers

- Access pre-built analytics, KPIs and build custom dashboards

- Seamless and secure integration to Google Cloud and other cloud platforms

- Setup, monitor and manage IIoT devices and deployments from a central location

Google Anthos

Bringing applications to the edge with Google Anthos

Litmus joined Google Cloud on their Anthos initiative to bring partner applications to the edge. Litmus can be deployed as a container in Google Anthos to run quickly and reliably, isolated from other processes.

- Modern container deployment of Litmus in Google Anthos

- Brings applications to the edge with 5G for rapid time-to-value

- Modern edge application platform purpose-built to scale