Case Study

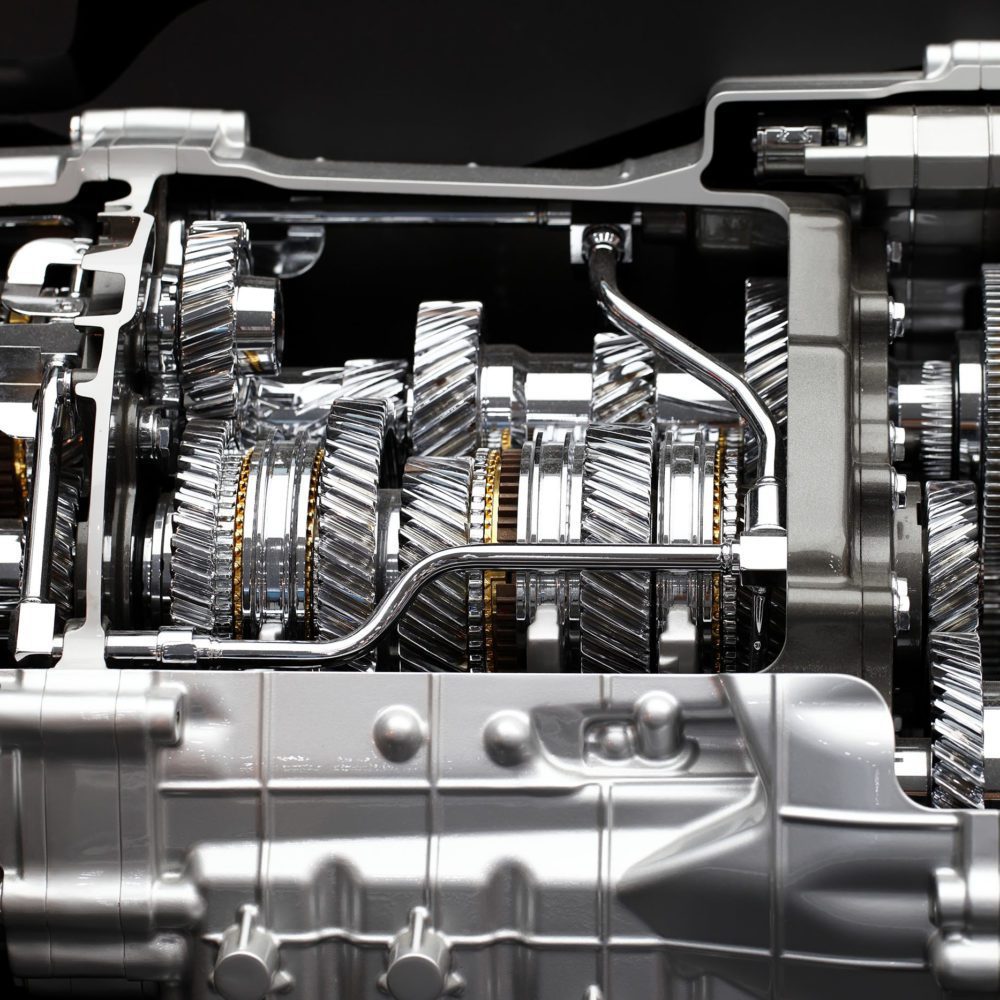

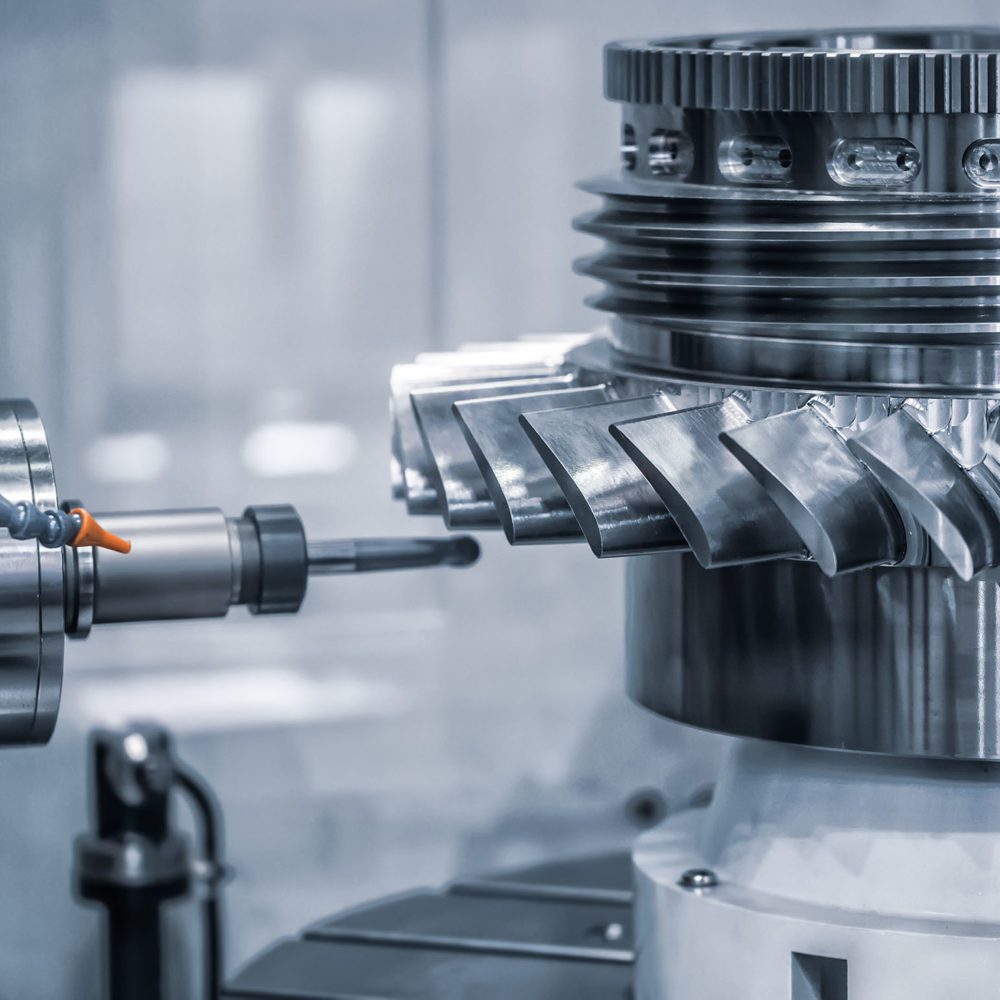

Global Automotive Supplier Connects Factories to the Enterprise

Litmus Edge connected the full breadth of OT and IT assets with out-of-the-box support for any driver, protocol or connection. Quick ROI on projects, zero disruption, and scale at own pace. The solution could integrate the data to any destination and was easy-to-use with little training required and a reasonable total-cost-of-ownership.

Instant and Offline Analytics

Building Materials

Quick ROI: $100K Savings Per Project

16,000 Employees

Rapid Deployment @ 20+ Plants

39 Plants

Challenges

- Data trapped in legacy machines;

20+ legacy assets per line. - Lack of visibility into the shop floor.

- Heterogeneous data (sensor, PLC data such as position, signals, machine status, and speed, utility meters, plant noise levels, DMC readers, quality status and rejections, etc.) and machine types (PLC, conveyors, CNC machines, etc.).

Outcomes + Benefits

- Standardized tagging, polling, flows across plants provided quick ROI for data projects

- Automated alerts on KPIs (e.g., cycle time, cutting wheel speed and pressure, cooling time, etc.).

- Real-time actionable analytics and KPIs at the edge; integration with Historian, SCADA, and MES data.

IIoT Success Stories

We’re proud to share challenges, results, projects and initiatives that Litmus Edge and our team have played a role in.

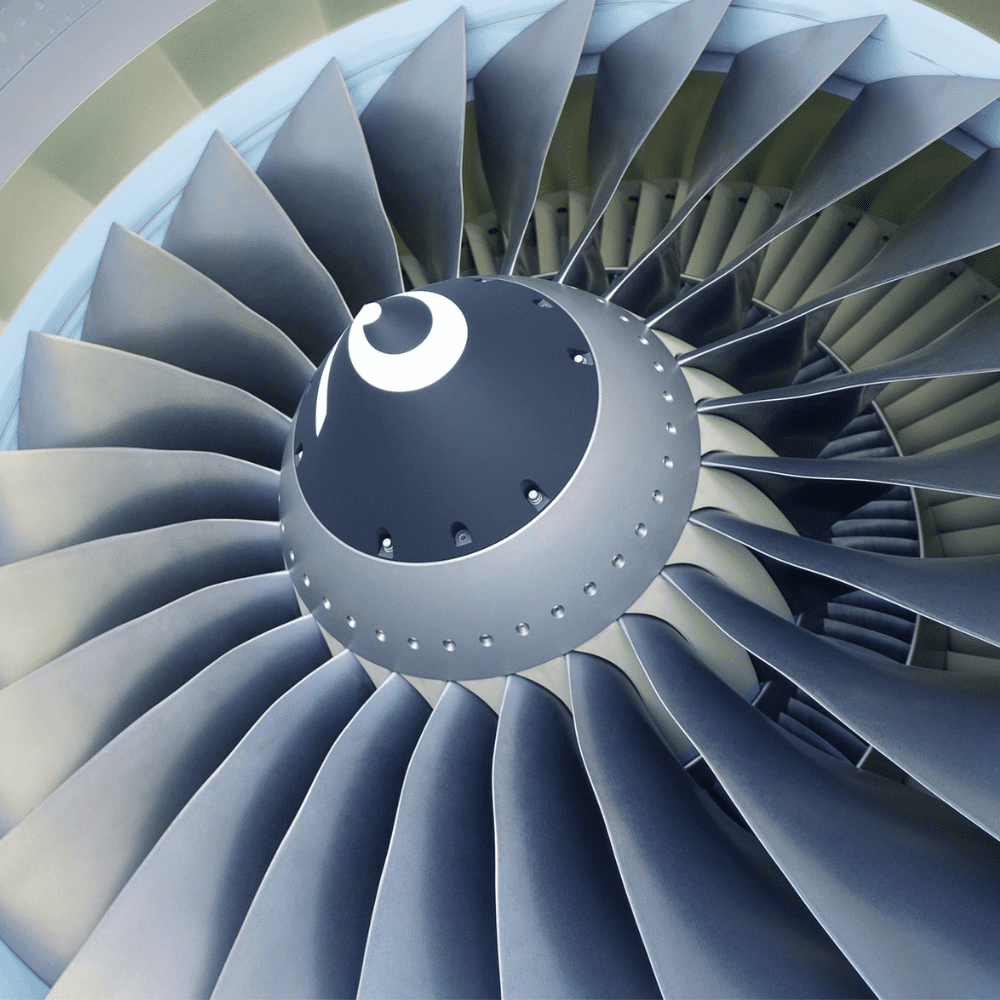

Aerospace Manufacturer Reduces Downtime and Improves OEE

Read More

Food Manufacturer Uses Agritech to Improve Crop Yield

Read More

Automotive Supplier Digitizes Manual Workflow

Read More

Industrial Machinery Manufacturer Increases Profits with IIoT

Read More

Tool Manufacturer Monitors CNC Machines for Quality Improvement

Read More

Cable Manufacturer Improves Quality and Reduces Manufacturing Costs With IIoT

Read More

Bottled Water Manufacturer Leverages OT Data to Improve Operations

Read More

Mining Company Augments SCADA with IoT Platform to Enable Predictive Maintenance

Read More

Food Manufacturer Achieves Complete Digital Transformation with Litmus

Read More