Case Study

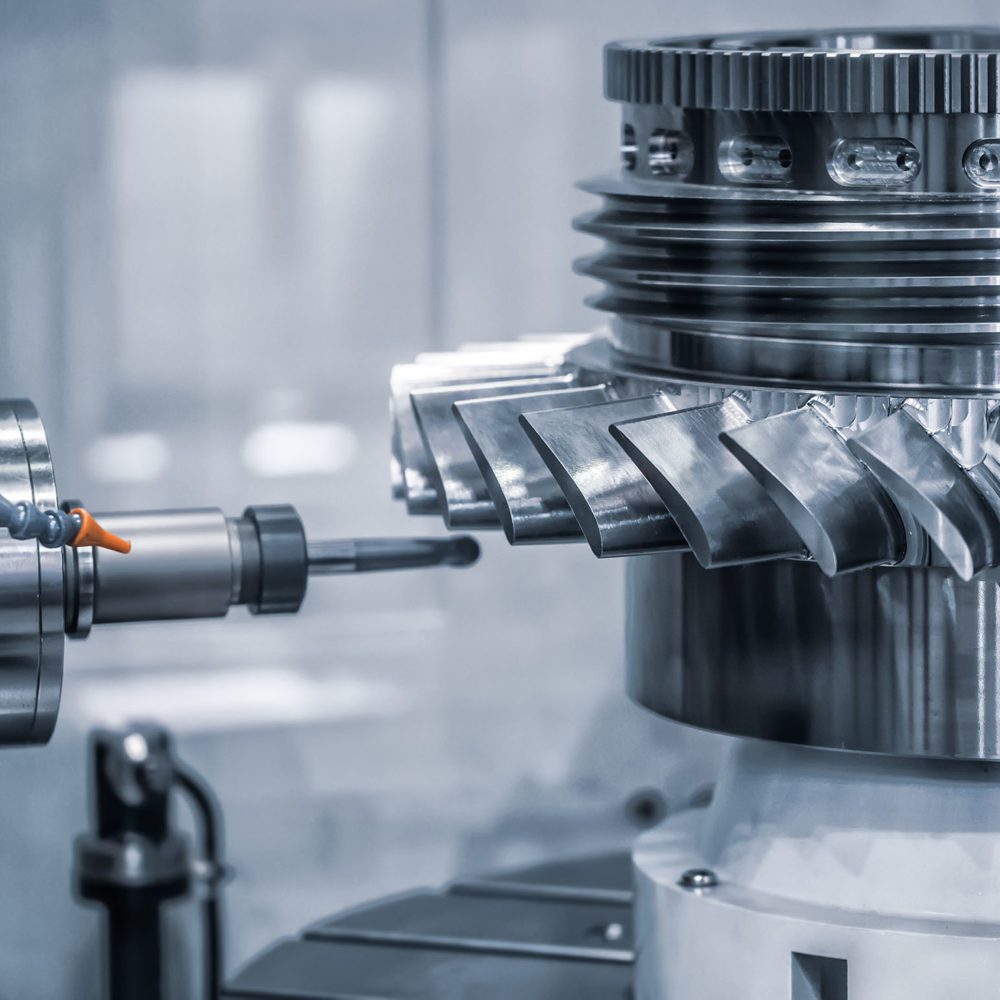

Tool Manufacturer Removes Digital Transformation Roadblocks

The customer unlocked the data trapped in specialized non-PLC machines, centralized data collection, and normalized it for advanced analytics in the cloud. This provided them with insights previously unavailable. The customer combined process, maintenance, and quality data for innovations in product design and productions alike.

Ease-of-Use, Low Code / No Code

Manufacturing & Construction

Simplified Digital Transformation

6000+ Employees

Cloud Analytics at Enterprise Scale

23 Plants

IIoT Success Stories

We’re proud to share challenges, results, projects and initiatives that Litmus Edge and our team have played a role in.

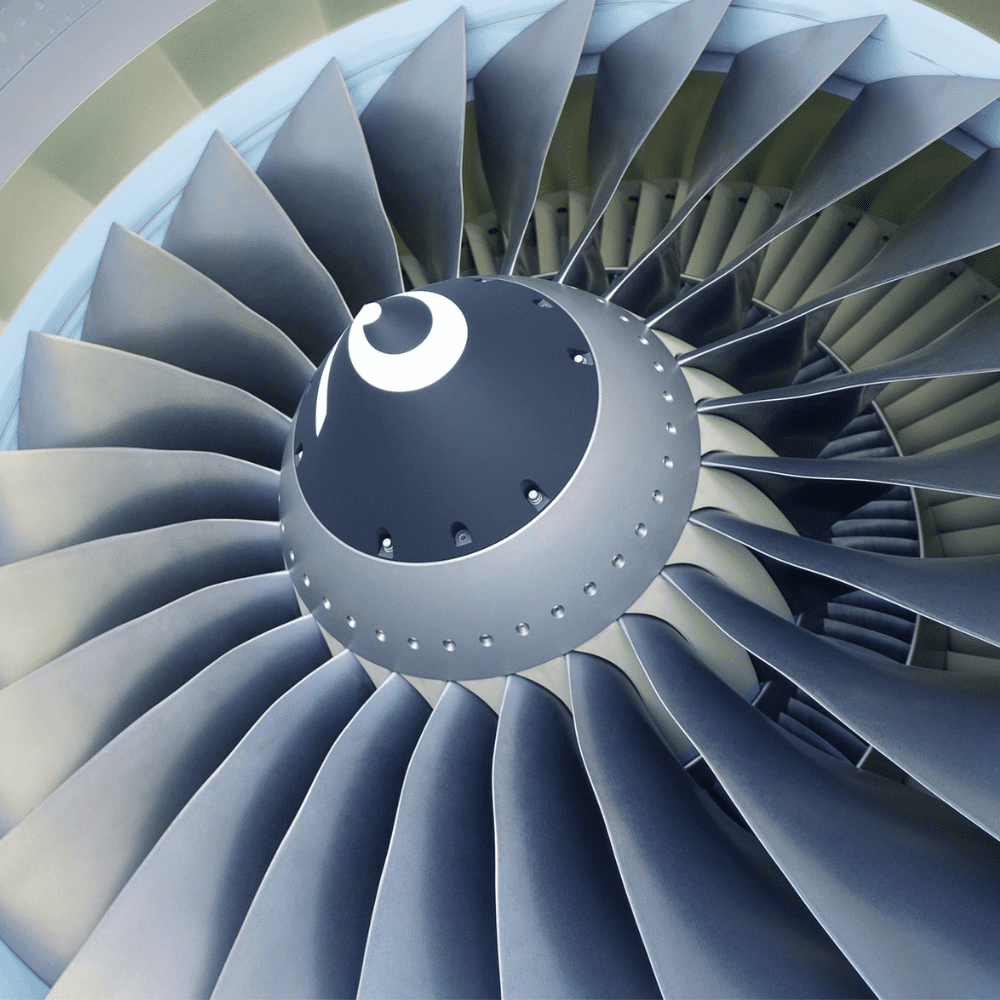

Aerospace Manufacturer Reduces Downtime and Improves OEE

Read More

Food Manufacturer Uses Agritech to Improve Crop Yield

Read More

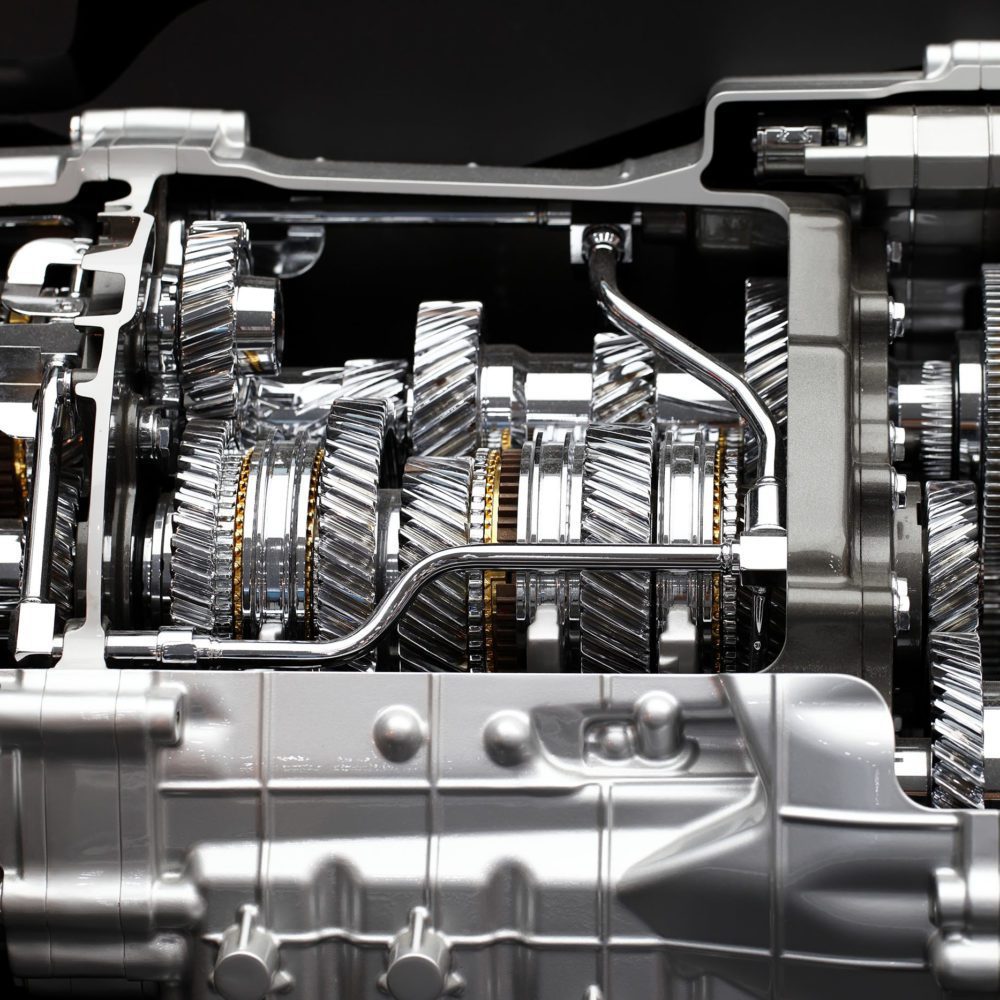

Automotive Supplier Digitizes Manual Workflow

Read More

Industrial Machinery Manufacturer Increases Profits with IIoT

Read More

Tool Manufacturer Monitors CNC Machines for Quality Improvement

Read More

Cable Manufacturer Improves Quality and Reduces Manufacturing Costs With IIoT

Read More

Bottled Water Manufacturer Leverages OT Data to Improve Operations

Read More

Mining Company Augments SCADA with IoT Platform to Enable Predictive Maintenance

Read More

Food Manufacturer Achieves Complete Digital Transformation with Litmus

Read More