In an era where data is heralded as the new oil, Industrial Data Operations—or DataOps—is rapidly becoming a cornerstone for enterprises striving to harness data for operational excellence and competitive advantage. However, shifting paradigms often bring along misconceptions. Today, let's dispel the top three myths surrounding Industrial DataOps and delve into the reality behind this transformative approach.

Get started with Litmus Edge!

Introduction to Industrial Data Operations

Industries across the globe are facing unprecedented challenges and opportunities, fueled by rapid technological advancements and the digital economy's pressures. At the heart of this transformation is data—its collection, analysis, and integration—driving efficiency, innovation, and competitive advantage. Industrial DataOps emerges as a pivotal catalyst, aligning digital transformation strategy with operational needs. This guide explores the myths, realities, strategies, and impacts of Industrial DataOps on manufacturing and broader industrial landscapes.

Learn more.

Decoding Industrial DataOps

Defining Industrial DataOps

Industrial DataOps stands at the convergence of data science, data engineering, and operations, aimed at enhancing data analytics, data integration, and data flow in industrial settings. This approach supports a comprehensive digital transformation strategy by ensuring that data is more accessible, reliable, and actionable across the organization.

Essential Elements of Industrial DataOps

Industrial Connectivity: Essential for Industrial DataOps, establishing strong connectivity solutions ensures smooth communication between different industrial devices and equipment. It is fundamental for the creation of networks that support dependable data transfer from production environments to digital platforms, facilitating immediate oversight and management. Integrating legacy systems with contemporary IoT technologies is crucial for enabling devices of various eras to interact seamlessly, thus enhancing data operations.

Data Acquisition & Standardization: Collecting data from diverse sources, including sensors, machinery, and operational systems, is a critical phase in the Industrial DataOps journey. By standardizing disparate data into a uniform format, it becomes compatible for further actions, such as analysis. This standardization is vital for enabling meaningful comparisons and calculations, which are essential for informed decision-making.

Data Processing & Analysis: Applying sophisticated analytics to evaluate the gathered data uncovers valuable insights. Visualizing these insights makes them accessible and understandable, transforming raw data into comprehensible, actionable intelligence. This enables decision-makers to easily grasp complex patterns and anomalies without needing to dissect the raw data themselves.

Contextualization and Data Modeling: Linking the gathered data with its relevant operational contexts significantly enriches the analysis, providing deeper insights. Embedding data within its real-world scenario helps businesses grasp the 'what' and the 'why' behind their data, enhancing understanding. Data modeling enhances this step by building a predictive and simulational framework for strategic decision-making based on a blend of current and historical data.

Data Integration: Merging data from different sources yields a holistic view, stitching together fragmented data for comprehensive analysis and insights. This integration facilitates cross-functional examination and insights, breaking down barriers between departments and ensuring a unified approach to leveraging data for broad business strategies.

Data Governance & Security: Enforcing well-defined policies, standards, and technological measures is crucial for ensuring data integrity and restricting access throughout data's lifecycle. This covers preventing unauthorized access or breaches, maintaining data consistency and trustworthiness, and complying with relevant regulations and privacy laws. Effective governance and security are cornerstones in preserving trust and safeguarding sensitive information.

Data Sharing: Promoting data exchange among stakeholders, including partners, vendors, and customers, fosters collaboration. Essential for an efficient, transparent, and responsive supply chain, data sharing enables all parties to refine their operations using collective insights, leading to enhanced collective outcomes.

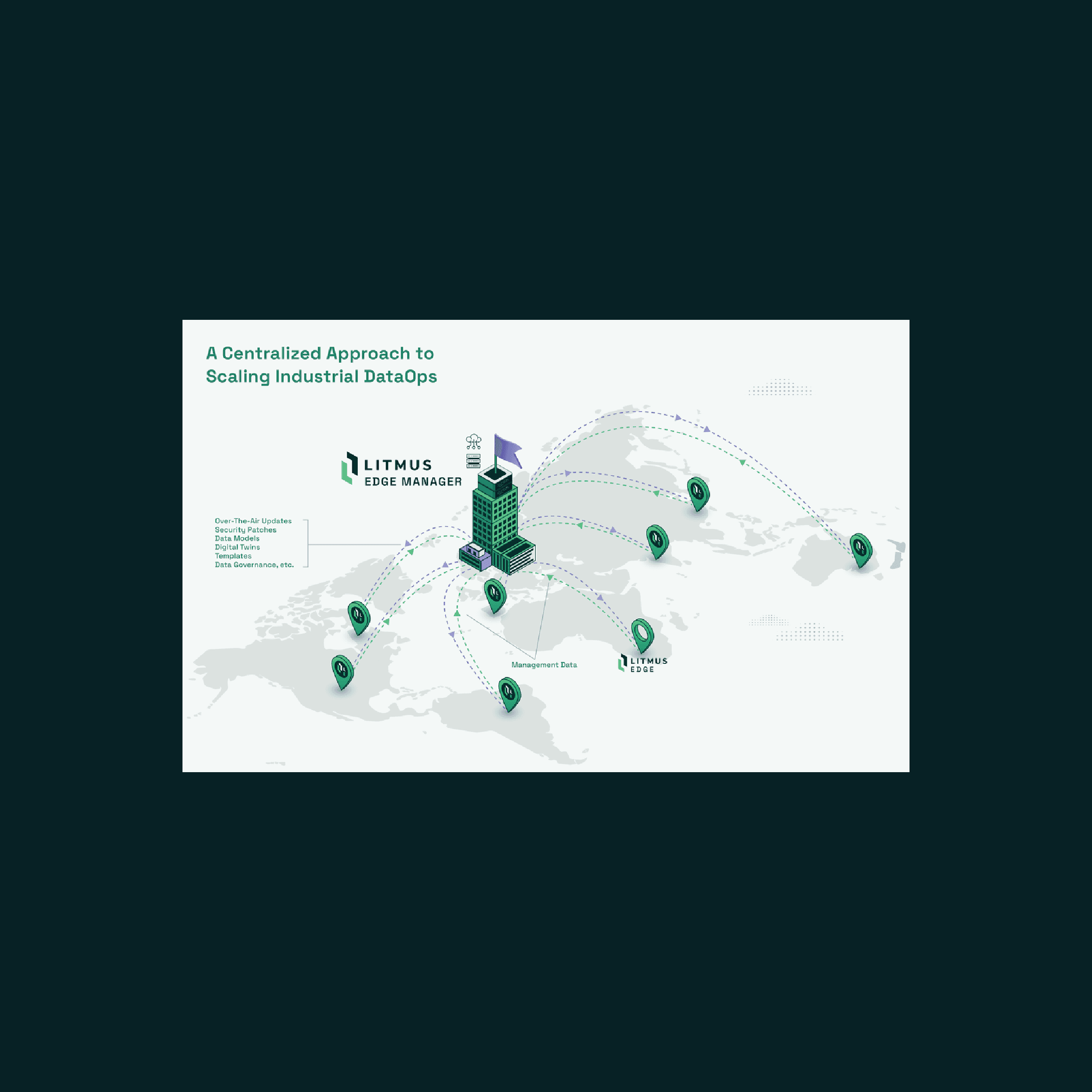

Managing Scale: Effectively addressing the challenges of escalating data volumes is essential, comprising the adoption of solutions and technologies designed for efficient large-scale data management concerning storage and analysis. Successfully scaling data management not only supports growth but also underpins more advanced analytics and machine learning endeavors.

Learn how Litmus Edge can deliver a unified industrial dataops journey.

Myth-Busting in Industrial DataOps

The implementation of DataOps in industrial settings comes with its fair share of myths that need dispelling to harness its full potential. Let's dive into each myth and uncover the truth behind it.

Myth 1: DataOps Is Just Advanced IT

There's a common perception that DataOps is merely the next step in the evolution of IT, implying it focuses solely on technology management.

Reality

Agile Methodologies: Unlike traditional IT that might follow a more waterfall approach to project management and delivery, DataOps incorporates agile methodologies that promote rapid, iterative cycles. This agility allows for continuous improvement and adaptation in data management, optimizing the entire data lifecycle from ingestion to insights.

Collaboration and Communication: DataOps emphasizes collaboration between teams (data scientists, engineers, operational staff, and IT) much more than traditional IT roles. It fosters a culture of communication and continuous feedback loops, ensuring that data processes are aligned with the organization's evolving needs.

Focus on Data Quality and Delivery: DataOps goes beyond maintaining systems and infrastructure by prioritizing continuous data delivery and quality. It integrates practices like version control, continuous integration/continuous deployment (CI/CD) for data, and automated testing to ensure data reliability and efficiency.

Myth 2: DataOps is Only for Big Data

A prevalent myth is that DataOps methodologies are designed solely for managing vast datasets or "Big Data".

Reality

Size Agnostic: DataOps principles are size agnostic; they apply to any scale of data. Whether a company deals with gigabytes or petabytes of data, DataOps can streamline processes, improve data quality, and enhance decision-making.

Small Data Benefits: Even businesses dealing with relatively small datasets can benefit from DataOps by leveraging strategies like automation, continuous delivery, and quality control. These practices help in making better, data-informed decisions quickly and efficiently, which is critical for businesses of any size.

Encourages Data Democratization: DataOps promotes the idea that data should be accessible and understandable to stakeholders throughout the organization, irrespective of the data volume. This democratization ensures that all decisions can be data-driven.

Myth 3: DataOps Eliminates the Human Element

There's a belief that DataOps, with its emphasis on automation and process efficiency, sidelines the importance of the human workforce in data management roles.

Reality

Complements Human Skills: Automation in DataOps is intended to complement, not replace, human skills. It takes over repetitive, time-consuming tasks, allowing data professionals to focus on more complex problem-solving, strategic planning, and creative thinking roles that add significant value.

Human-Centered Design: DataOps involves designing processes and systems with a human-centric approach. This includes understanding user needs, ensuring the interpretability of data, and making data-driven decisions that consider the social, ethical, and business contexts.

Critical Role in Strategy and Execution: Humans are essential for understanding complex data, making strategic adjustments, and making decisions that match the overall goals of a business. This human insight is crucial for navigating the vast sea of data and analytics to drive meaningful outcomes.

The Industrial DataOps Strategy

Implementing a successful Industrial DataOps strategy involves several steps:

1. Assessment and Planning

Evaluating current data capabilities, identifying gaps, and planning for integration of DataOps principles into the existing digital transformation strategy.

2. Technology and Tools

Selecting the right mix of technologies and tools that facilitate effective data collection, analytics, integration, and management.

3. Process Development

Developing processes that support agile data operations, continuous improvement, and cross-functional collaboration among data scientists, engineers, and operational staff.

4. Culture and Training

Fostering a culture that values data-driven decision-making and investing in training to develop the skills necessary for implementing and sustaining DataOps practices.

Challenges of Implementing Industrial DataOps

Businesses nowadays are really into using data to make their decisions smarter and faster. This is like collecting lots of information from everything happening in the company to try and figure out the best moves forward. But there's a big issue that's sort of like the huge, awkward problem nobody wants to talk about: when companies try to use all this data across lots of different places in their business, it gets really tricky.

At the start, when a company begins to gather lots of data, they feel like they've hit a goldmine. But just having a bunch of data isn't the same as really being able to use it well, especially when you've got to do it all over the place in lots of different locations.

Many businesses think once they have the data, their problems are solved. This might work fine when they're looking at just one area or a small group of locations. But as soon as they try to do the same thing everywhere, they run into big problems. Using data smartly across a whole company is not about just doing the same thing everywhere. It requires a plan that is flexible and can adjust to different needs.

This means that if businesses really want to make the most of their data, they need to stop avoiding the big awkward issue and start working on a way to handle data that works everywhere in the company. That includes making sure data is treated the same way across all areas, and that they can quickly change plans based on new information or needs.

In simple terms, it's not enough to just celebrate getting lots of data. The real win is figuring out how to manage and use that data everywhere in the business effectively. Confronting this big challenge isn't easy, but it's a must-do for businesses that want to make smart decisions and stay ahead.

Read this mini-paper on the real challenge of scaling industrial data operations.

The Impact of Industrial DataOps on Digital Transformation

Integrating Industrial DataOps into a digital transformation strategy unfolds a multitude of influential impacts, profoundly reshaping how industries function, innovate, and compete.

Enhanced Operational Efficiency

The incorporation of Industrial DataOps streamlines the flow of data throughout an organization. By establishing robust connectivity and ensuring the seamless exchange of information across various devices and platforms, companies can significantly reduce bottlenecks and inefficiencies inherent in their processes. Furthermore, the application of advanced analytics to processed and normalized data leads to more informed decision-making. This fosters not just a reactive but a predictive approach to operations, where potential issues can be addressed before they escalate and opportunities can be seized more rapidly. Consequently, organizations witness a marked improvement in their operational efficiency, with optimized production timelines, reduced waste, and more agile response capabilities.

Fueling Innovation

The impact of Industrial DataOps extends into the realm of innovation. With real-time data capture and analysis, businesses gain access to insights that were previously unattainable. This wealth of information becomes a catalyst for product development and enhancement, enabling companies to tailor their offerings more closely to customer needs and preferences. Adaptive manufacturing techniques, powered by the insights derived from operational data, allow for more flexible production processes that can easily adjust to new trends or demands. Therefore, the dynamic nature of data-driven innovation not only paves the way for groundbreaking products and services but also for improved methodologies and operations that ensure sustainability and growth.

Securing Competitive Advantage

At its core, the ability to swiftly adapt and respond to market changes and customer needs is what sets leading companies apart from their competitors. Industrial DataOps equips organizations with the agility to do just that. By harnessing and effectively leveraging the power of data, businesses can anticipate market trends, understand customer behavior, and adapt their strategies accordingly at an unprecedented pace. This foresight and agility confer a significant competitive advantage, enabling companies to not only meet but exceed customer expectations, capture new markets, and respond effectively to competitive pressures. The ability to quickly turn data into actionable insights means these organizations are always a step ahead, ready to innovate and transform challenges into opportunities.

Case Studies: Industrial DataOps in Action

Several industrial companies have successfully integrated DataOps into their operations, demonstrating its value. Through real-world applications, these companies have seen substantial improvements in efficiency, product quality, and market responsiveness.

Check out Litmus' customer success stories.

Future Trends in Industrial DataOps

The evolution of Industrial DataOps is likely to be influenced by advancements in technology, such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies promise to further enhance the capabilities of DataOps, providing even greater insights and efficiencies.

Furthermore, as industries continue to navigate digital transformation, the role of data becomes increasingly strategic. Organizations will seek to not only collect and analyze data but to seamlessly integrate insights into every facet of their operations. This integration will demand more sophisticated DataOps strategies, combining innovative technologies and methodologies to drive success in the evolving industrial landscape.

Conclusion

Industrial DataOps is more than a buzzword; it's a strategic approach that integrates data collection, analytics, and integration to drive digital transformation in manufacturing and other industries. By dispelling the myths and understanding the methodologies, technologies, and human elements involved, companies can leverage Industrial DataOps to achieve superior operational intelligence, innovation, and competitiveness. As industries forge ahead, the principles of DataOps will become increasingly integral to navigating and excelling in the digital era.

Try Litmus Edge today or speak with our team of experts about how we can help you leverage industrial data as a strategic asset in driving your digital transformation success story.