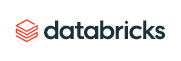

Oracle Cloud is your Industrial AI platform—and Litmus provides the real-time data foundation to bring it to life. As a certified Oracle partner, Litmus offers contextualized OT data at scale through one edge data platform for everything Industrial AI. By connecting thousands of assets across hundreds of sites in minutes, it helps you achieve faster, smarter, and more reliable AI results.

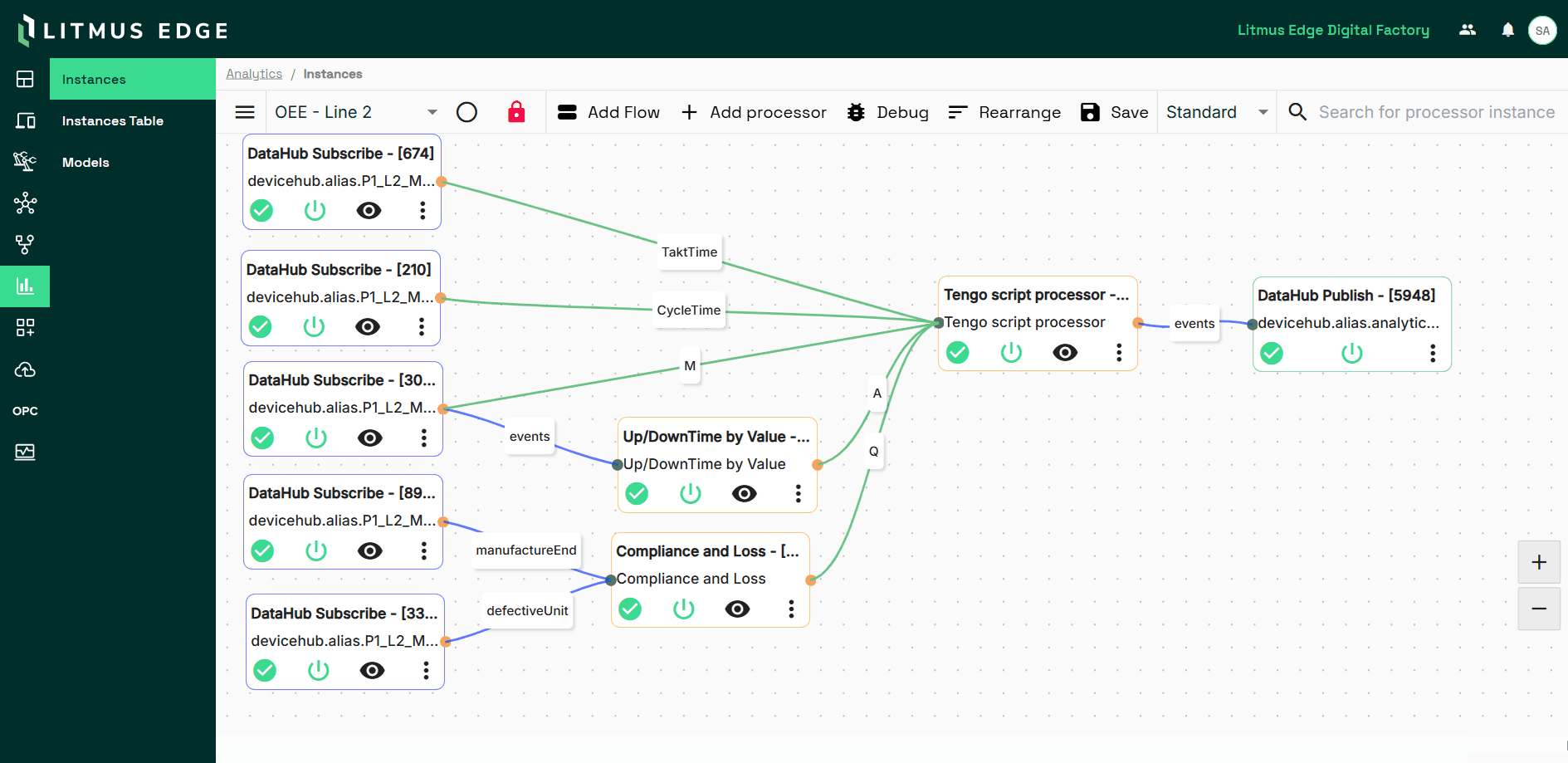

ACTIONABLE OT DATA AT THE EDGE

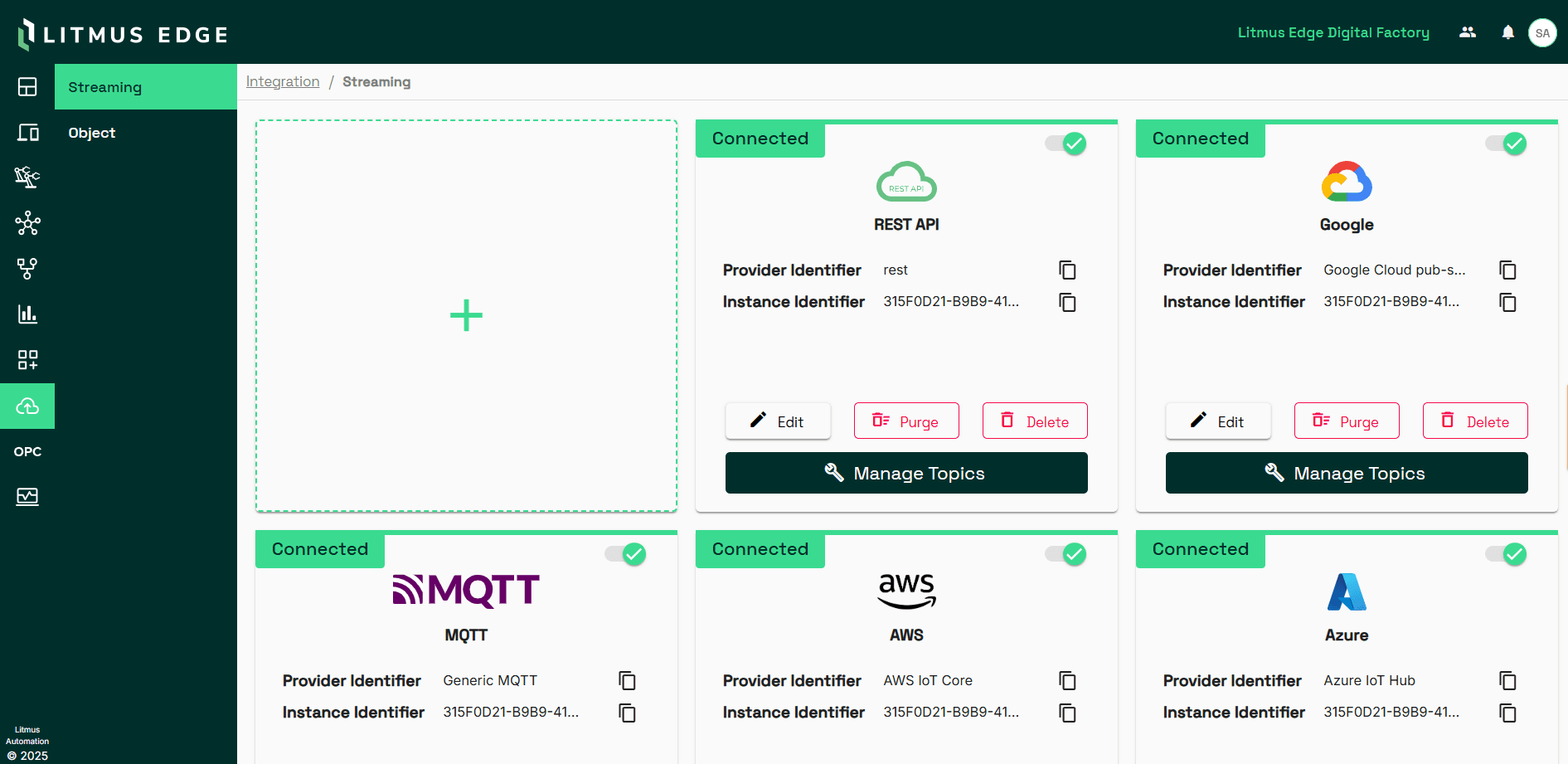

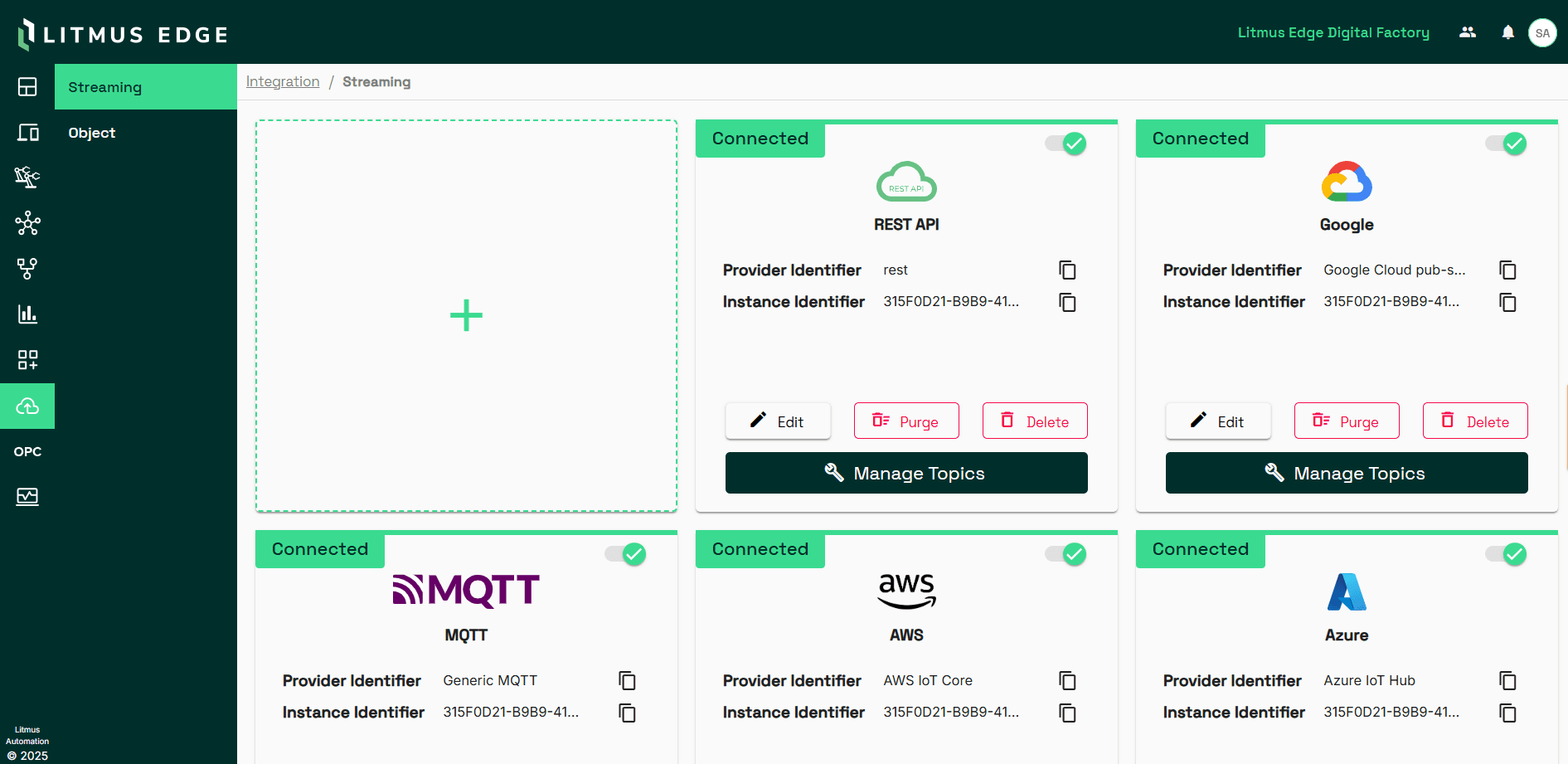

Litmus collects, contextualizes, and analyzes OT data locally, delivering structured, event-driven insights to Oracle Cloud without overwhelming your systems.

TARGETED OT-IT INTEGRATION

Feed Oracle’s AI-driven Smart Operations with precise, actionable data to automate alerts, optimize assets, and enhance production.

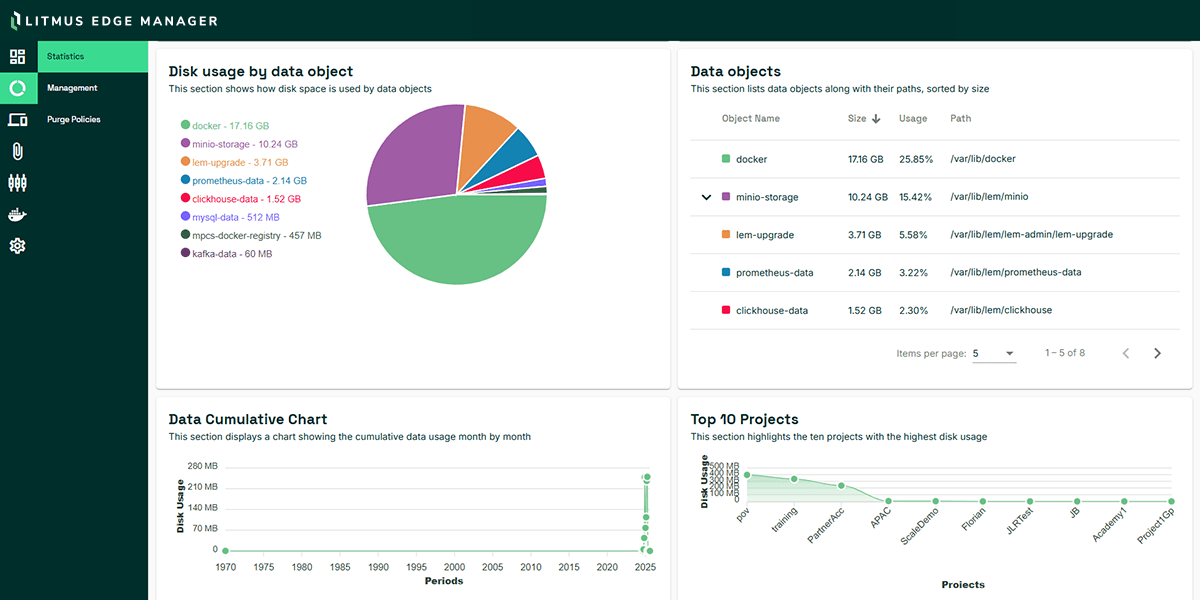

SCALABLE ORCHESTRATION & CONTROL

Easily deploy and govern Litmus across sites with containerized apps, standardized templates, and centralized monitoring without disrupting operations.

ENTERPRISE SECURITY & COMPLIANCE

Protect your data pipeline with robust encryption, role-based access, and compliance with Microsoft and Oracle standards.

Enterprise Use Case

| Industrial AI | Enterprise Analytics | OT-IT Convergence |

|---|---|---|

| Feed clean, real-time edge data into AI models for faster deployment and scalable intelligence across sites. | Standardize and send OT data into analytics tools without manual prep. Get actionable, cross-site visibility. | Bridge legacy OT systems with IT cloud platforms for unified, governed data across the enterprise. |

Operation Use Case

| OEE Optimization | Asset Monitoring | Predictive Maintenance |

|---|---|---|

| Improve efficiency and reduce downtime by monitoring and improving machine performance in real time. | Monitor asset health with immediate alerts on vibration, temperature, etc. | Utilize real-time diagnostics and edge analysis to detect patterns of failure early, before downtime occurs. |

Disconnected systems create delays, scrap, and risk. With Litmus + Oracle, your data becomes a strategic asset, delivered where it’s needed, when it’s needed, and in a form your teams can act on. From asset health to predictive quality, it’s the foundation for scalable digital manufacturing.