The Litmus Industrial Innovation Hub in Santa Clara stands as a testament to our journey from humble beginnings to becoming a cutting-edge center for Industrial DataOps innovation. In this article, Parth Desai, Director of Solutions and Industrial at Litmus and one of our founding engineers, shares the story of how this facility has developed and evolved.

Our Journey and Shift to a New Platform

Can you tell us about the early days at Litmus and how the Santa Clara office became an innovation hub?

Absolutely. Our journey began in June 2016 when I joined the three founders as the first engineer. Initially, we focused on data collection and management. However, our direction shifted when a potential customer, a boiler manufacturer, sent us a single PLC to collect data. This pivotal moment led us to create a comprehensive edge management platform, which we now know as Litmus Edge.

Building the CI/CD Lab

How did the need for a robust testing environment shape the development of your CI/CD lab?

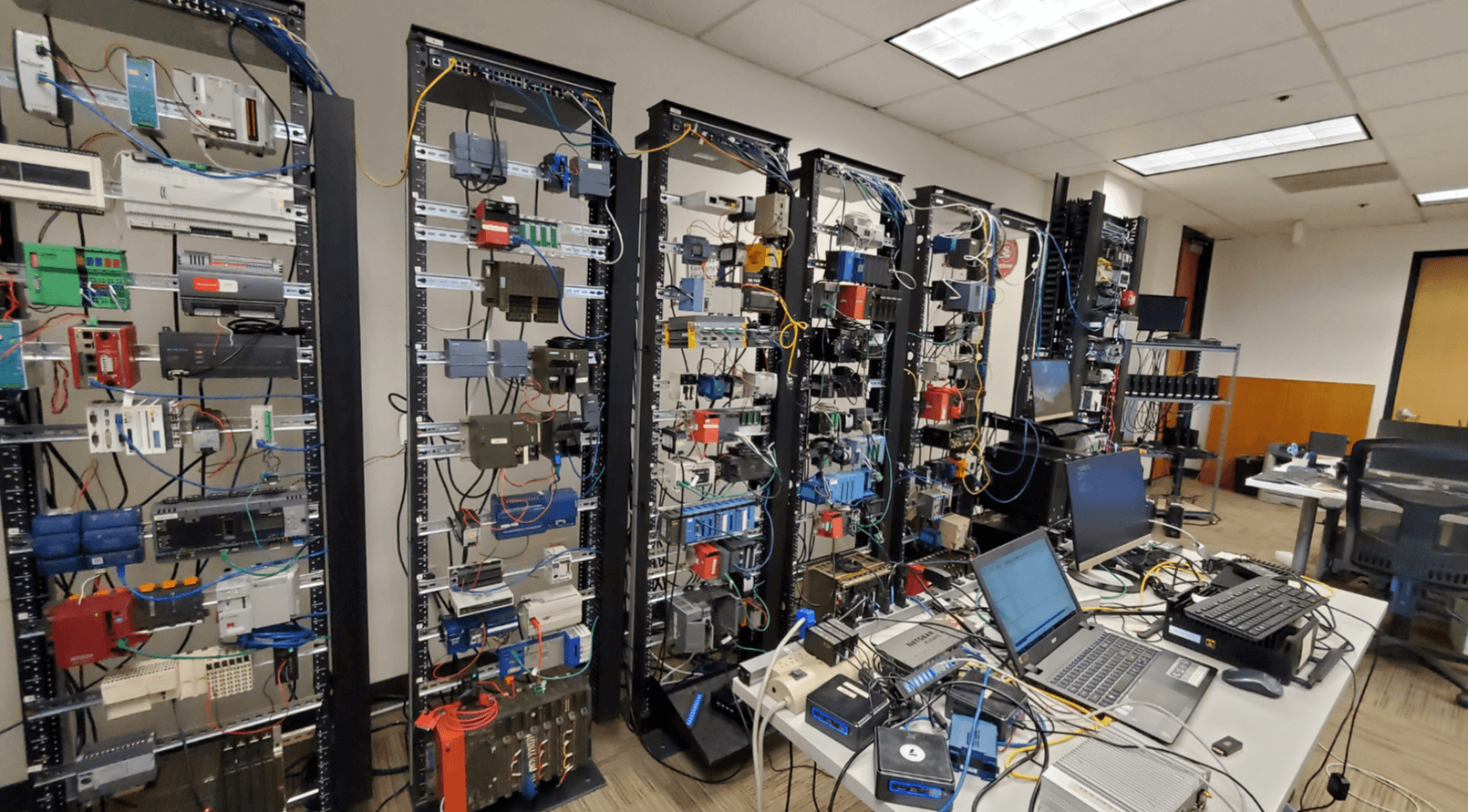

As we transitioned, we recognized the need for a strong testing environment. This led to the creation of our Continuous Integration/Continuous Deployment (CI/CD) lab in Santa Clara. The lab features different racks organized by vendors and protocols, simulating real plant floor environments. This setup ensures that every line of code we develop is thoroughly tested across various systems and protocols, including serial communication and Ethernet.

The Evolution of Our Lab

How has your lab evolved over time?

Our lab started out from modest beginnings, with most of our initial PLCs sourced from eBay due to their end-of-life status and lack of vendor availability. Over time, our collection grew, allowing us to simulate a wide range of industrial environments. Today, our lab hosts devices from the 1980s to the latest models, providing a comprehensive testing ground for both hardware and software. This evolution has been critical in building our credibility and capabilities.

Comprehensive Communication Module Coverage

What is a key focus of your lab in terms of communication module coverage?

A key focus of our lab is ensuring comprehensive communication module coverage. For different vendors and PLC modules, we don’t just develop one driver. For example, if a PLC has Ethernet, we develop data collection capabilities using Ethernet, but we don't stop there. We also cover other methods like serial communication. Our goal is to ensure that regardless of the communication module—whether it's serial or Ethernet—our driver works. This is crucial because the same PLC can differ from one customer to another.

Real-Time Simulation and Driver Development

How do you ensure that your solutions are as close to real-world conditions as possible?

In addition to driver development, we emphasize real-time simulation. We create pseudo-programs with the same cycle time as actual plant floors to simulate how the PLC would work in real conditions. This ensures our solutions are as close to real-world conditions as possible. Sometimes, customers send us their proprietary PLC programs when they lack in-house expertise to extract tags they would find helpful[PD1] . We then develop drivers remotely using our Driver Development System (DDS). This system allows us to ship a DDS box with preinstalled tools and dual LAN ports, connecting to customer networks and developing drivers without needing physical access to the hardware.

Real-World Challenges and Solutions

Can you share an example of how you address real-world challenges?

Our lab goes beyond just simulating perfect conditions; we tackle real-world challenges. For instance, while in South Korea, I had to connect to an old PLC S5 from the 1980s, written in German, without any documentation. Using Google Translate and a lot of trial and error, I managed to get the driver running. This experience demonstrates our commitment to solving even the toughest problems. We understand that customers may not always have the latest equipment or documentation. That's why we work closely with them to understand their issues and provide tailored solutions. We also have Solution Accelerators available on the central portal, which our customers and partners can use for their Litmus Edge deployments.

Establishing Industry Partnerships

How do industry partnerships play a role in your work at Litmus?

Parth Desai: One of the most rewarding aspects of my role as Director of Solutions and Industrial here at Litmus has been nurturing our hardware partnerships. Companies like Emerson, Parker, HP, and Dell send us their latest hardware for testing and certification. These partnerships are crucial, allowing us to validate our platform’s compatibility with a wide range of industrial devices. Our lab’s reputation has grown, attracting companies like Palo Alto Networks and NTT Data to use it for developing and testing their solutions. In fact, many companies come to us specifically for our lab, such is its standing these days.

Strategic Location and Legacy

Why was Santa Clara chosen as the location for your lab, and what significance does it hold?

Choosing Santa Clara for our lab was a strategic decision. Our first office was in San Jose, but as we grew, we moved closer to Intel, where Silicon Valley began. The term Litmus has been around for 120 years, symbolizing our commitment to consistency and problem-solving. This location aligns perfectly with our goals and vision, placing us at the heart of technological innovation.

The Backbone of Litmus's Success

How important is the Santa Clara lab to Litmus' overall success?

Our Santa Clara lab is more than just a testing ground. Over the years, it has morphed into becoming the backbone of our success. The ability to simulate real-world conditions, develop solutions collaboratively with customers, and maintain a comprehensive suite of tested devices is, as far as we know, unique to us in the IIoT world. It ensures that we remain at the forefront. The lab’s ongoing evolution reflects our commitment to innovation and excellence too, making it a critical asset in our mission to drive the future direction of industrial dataops.

What makes the Santa Clara office unique in terms of industrial expertise and innovation?

The Santa Clara office is a hub of industrial expertise, continuous innovation, and strategic partnerships. It exemplifies how a well-designed, continuously evolving lab can drive company success and industry advancement. With a dedicated team and a strategic location, Litmus is well-positioned to continue leading the Industrial DataOps revolution. Our journey has been challenging yet rewarding, and I am proud to be part of this incredible story.

Thank you, Parth! It’s been great chatting with you. Before we wrap up, do you have any final thoughts to share?

Absolutely. As we look to the future, the Litmus Industrial Innovation Hub in Santa Clara will keep driving advancements in Industrial DataOps. Our focus on excellence, strategic partnerships, and cutting-edge technology will help us stay ahead.

Great stuff! If people want to learn more or get involved, what should they do?

If you're looking to improve your operations or find innovative solutions, check out our website or get in touch with us directly. We're here to help you start your journey with Litmus!