Dave McMorran

Director of Sales Engineering

Wondering whether the legacy systems of record can be augmented to meet the demands of tomorrow’s goals?

Doing More With Data is not a one-time act. It’s continuous.

The journey to “Do More With Data” begins with a clear understanding of the business problem that needs to be solved. This is often the most difficult step, as it requires companies to take an honest look at their operations and identify areas where data can have an impact. Doing More With Data is not a one-time act. It’s continuous. It requires companies to constantly evaluate their data strategy and adjust as needed. It also requires companies to be agile in their approach, as the business environment is constantly changing.As the digital age leans more into the era of data dominance, the phrase “Do More With Data (DMWD)” has become increasingly significant. Industrial companies, whether in manufacturing, energy production, construction, or other sectors, generate a trove of data daily. Understanding how to leverage this resource efficiently represents an enormous competitive advantage.Industrial companies can use data to make better decisions about how they operate, what products they produce and how they sell them. For example, a manufacturer might use data on customer preferences to determine which features are most important in a new product line. Or an energy company could use data on weather patterns and demand for electricity to optimize its generation capacity.

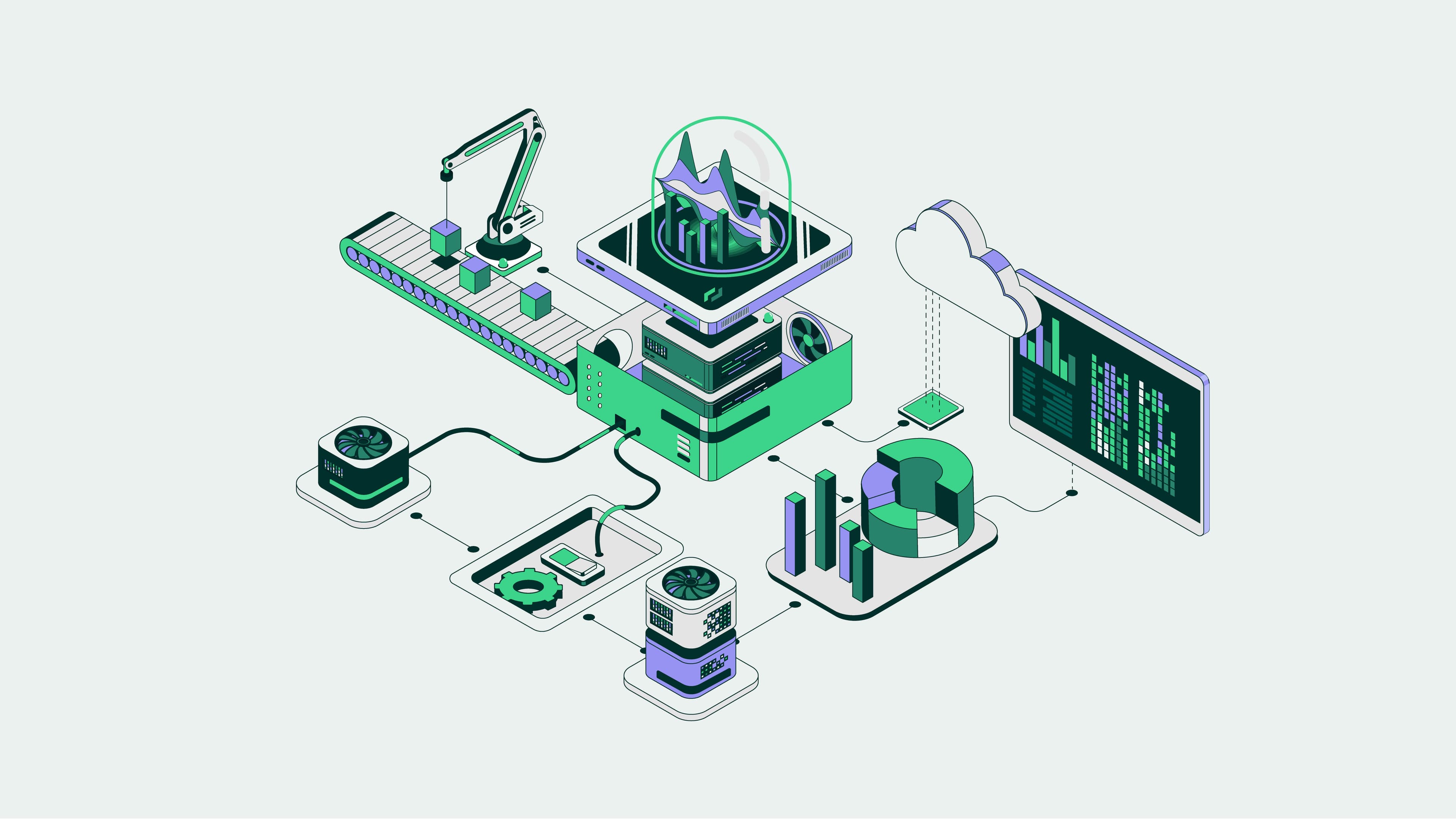

Understanding the vast potential of data is one thing, but knowing how to navigate the journey is equally important. For industrial companies looking to leverage the power of data, the ‘Do More With Data’ framework offers a systematic approach. This framework consists of five essential stages – Collect, Contextualize, Analyze, Integrate, and Act & Scale. Let’s delve into each.

1. Collect

Data collection is the first step in this framework. Here, industrial companies should focus on gathering as much relevant data as possible from a variety of sources, such as sensors, machinery, systems, processes, or external entities like supply chain partners. The emphasis lies in not only collecting high volumes of data but also ensuring its quality and relevance to your specific industry and objectives.

2. Contextualize

After collecting data, the next step is to add context to the data in a manner that makes it actionable. This involves building a robust data infrastructure that supports meta data storage, management, and accessibility. In essence, context serves as the indispensable environment in which the data lives. It gives meaning to raw data and powers its transformation into useful information.

3. Analyze

Once the data has more context, it must be analyzed to extract meaningful insights. Use statistical analysis, machine learning, and artificial intelligence to turn complex data-sets into insightful information – right where the data lives. At this stage, data scientists, data analysts, and other skilled professionals play a pivotal role in identifying patterns, correlations, and trends that can drive business decisions or reveal potential problems.

4. Integrate

Following analysis, it’s time to integrate the data with advanced visualization, storage and compute platforms in the Cloud. This represents a crucial step that transforms raw data into interactive graphs, charts, or other visual forms. This aids in understanding the extracted information better and spotting trends or patterns more easily. It can also help quickly share insights with external stakeholders or the rest of the value chain – eliminating ambiguity for better decision-making.

5. Act & Scale

The last and most vital step in this framework is action and the pathway to scale. Use the insights derived from data to drive decision making, improve efficiency, mitigate risks, foster innovation, or enhance customer experiences. The real value of data lies in how it informs actions that lead to tangible business outcomes – in a reasonable timeframe that can truly produce positive business outcomes.

1. Enhanced Operational Efficiency

By doing more with data, industrial companies can optimize operational performance. This involves using historical and real-time data to spot efficiency gaps, improve production processes, minimize downtime, and proactively manage machinery maintenance. A data-centric approach cuts waste and reduces costs, leading to significant efficiency gains.

2. Predictive Analysis

Predictive analytics uses data, algorithms, and machine learning techniques to predict future outcomes based on historical data. In an industrial setting, this could signify forecasting equipment failures, production bottlenecks, or supply chain disruptions. It allows industrial firms to anticipate problems before they occur, enabling them to take preventative actions.

3. Personalized Customer Experience

In today’s hyper-connected world, customers insist on personalized experiences. To meet these expectations, industrial companies can use data not only to understand customer behavior but also to tailor their products and services to each customer’s unique needs. This approach can boost customer satisfaction and loyalty, thereby improving market share and revenue.

4. Risk Management

Industrial companies face a myriad of risks, from equipment malfunctions to cyber threats. Data can provide insights into vulnerabilities and threats before they turn into severe problems. Behavioral data can even detect irregularities or anomalies that may precede cyber-attacks, providing an invaluable layer of security assurance.

5. Innovation and Product Development

Finally, a data-driven approach affords novel insights that can spur innovation. By understanding customer needs, market trends, and competition, industrial organizations can use data to drive their product development processes, innovate, and keep ahead of the global curve.

The bottom line for industrial companies is that “doing more with data” can offer considerable operational and strategic advantages. However, embracing a data-centric approach involves developing robust data infrastructure, training personnel, and fostering a corporate culture that values data-driven decision-making – a culture that values data as an asset and uses it to inform decisions, improve processes, and drive innovation. A culture that is not only embraced by the C-suite but also permeates throughout the organization—from top to bottom.

Companies that master these intricate challenges stand to gain operational efficiency, improved risk management, enhanced customer experiences, and a wellspring of innovation. Embracing a new phase of digital evolution and doing more with data is no longer a choice – it’s an imperative.Litmus Edge streamlines data collection and contextualization, turning raw data into actionable insights for industrial companies. As a unifying platform, it empowers efficient analysis, integration, and visualization, facilitating informed decision-making across the organization.

Ask for a personalized demo today to see the platform in action.

Vatsal Shah

Co-Founder + CEO

Vatsal Shah is the co-founder and CEO of Litmus.

Dave McMorran

Director of Sales Engineering

Wondering whether the legacy systems of record can be augmented to meet the demands of tomorrow’s goals?

Dave McMorran

Director of Sales Engineering

In manufacturing, embracing digital transformation is crucial. Litmus Edge simplifies the Unified Namespace (UNS) architecture, making it seamless to transition to digital and thrive in the modern landscape.

Suranjeeta Choudhury

Director Product Marketing and Industry Relations

Earlier this week, we announced the launch of Private Beta of Litmus MQTT – the world’s first ever enterprise-grade MQTT broker that’s actually built for Industrial IoT. The Private Beta version is now open for early access sign-up.