Understanding the Challenge

In the industrial realm, the ambitious vision of scaling Industry 4.0 is reshaping the operational landscape. The goal is profound but not without challenges, primarily due to the complex nature of Operational Technology (OT) infrastructures. As Information Technology (IT) advancements like cloud computing, Business Intelligence (BI), mobile apps, and revolutionary fields such as Machine Learning (ML) and Artificial Intelligence (AI) progress, the chasm between OT and IT widens significantly.

Moreover, the industry has seen a proliferation of tools and software solutions that address isolated issues without considering the holistic picture. This piecemeal approach often misconstrues the essence of Industry 4.0, which is not about isolated use cases or individual sites or protocols. Rather, it emphasizes a smarter, interconnected systems approach to achieve broader business objectives and enhance manufacturing efficiencies.

Download your free copy of the Industrial DataOps Buyers Guide.

Drawing Parallels with The Traveling Salesman Problem (TSP)

To the community of data scientists, the scenario might resonate well with the classical Traveling Salesman Problem (TSP) in computer science. At its core, the TSP is a quintessential problem that seeks to delineate the shortest possible journey that visits each city once before returning to the origin. This problem is a neat, theoretical overlay for the complicated, interconnected pathways of the industrial landscape, where efficiency and optimization are paramount.

In the orchestration of Industry 4.0, envision each "city" as a distinct integration point or a technological upgrade nestled within the operational technology (OT) and information technology (IT) infrastructures. The formidable task lies not merely in touching each of these points but in charting a course that is most expedient, cost-effective, and beneficial to the overarching objectives.

Drawing parallels with the TSP illuminates the multifaceted nature of this challenge:

Optimization is Key: Just as with TSP, where the goal is to minimize the total distance traveled, in Industry 4.0, the aim is to optimize processes, reduce waste, and elevate efficiency.

Complex Decision-Making: Similar to the in-depth analysis and predictive insights needed to solve TSP, implementing Industry 4.0 technologies requires a nuanced understanding of how different components interact and influence one another.

Strategic Planning and Sequencing: Identifying the most effective sequence of visits in TSP mirrors the need for strategic planning in Industry 4.0, ensuring that each technological integration happens at the right juncture to support and enhance the next step in the process.

Inherent Uncertainties: Just as TSP solvers must contend with variables and uncertainties, so must those steering the Industry 4.0 initiative navigate the vagaries of market dynamics, technological advancements, and organizational change management.

The Role of Advanced Technologies: In solving TSP, sophisticated algorithms and computational techniques are employed, paralleling the advanced solutions like machine learning, AI, and edge computing that drive Industry 4.0 forward.

Speak to us about how Litmus has helped industrial data teams solve their challenges.

Charting the Optimal Path: Learning from TSP

How, then, can the principles that solve the TSP be applied to Industry 4.0 implementations? In the quest to navigate the complexities of implementing Industry 4.0, selecting a technology that not only addresses the myriad challenges but also seamlessly integrates various data points is essential. The key lies in choosing a solution that is comprehensive – one that offers a unified approach to solving data challenges, thus streamlining the path towards industrial evolution. More crucially, this technology should transform data from a mere operational byproduct to a strategic asset, empowering organizations to unlock new levels of efficiency and innovation.

Strategic Decisions in Build vs. Buy

When navigating the complexities of Industry 4.0, the strategic decision between building custom solutions (Build) versus purchasing ready-to-use products (Buy) becomes highly consequential. This dilemma can be likened to deciding whether to compute a new solution to the Traveling Salesman Problem for each unique journey or utilizing a proven, optimized path that has been abstracted from years of data and refinement. The latter approach not only guarantees a faster deployment but also ensures efficiency and reliability, drawing from established best practices and cutting-edge technology.

Litmus Edge exemplifies the advantage of the Buy strategy. By incorporating this platform, businesses are not sidetracked by the immense resource investment required to develop, test, and optimize from scratch. Instead, they can leverage Litmus Edge's proven technology to expedite the connection, analysis, and automation of data across the industrial environment. This not only speeds up the implementation but also enhances operational efficiency more swiftly and securely. Organizations can, therefore, focus their valuable resources on scaling solutions and innovating further, rather than reinventing the wheel. This strategic decision aids companies in not just reaching their destinations but doing so more effectively, tapping into the existing and sophisticated pathways carved out by expert solutions like Litmus Edge.

Siloed attempts to address Industry 4.0 hurdles are akin to the traveling salesman taking longer, potentially circuitous routes that may not guarantee a timely or efficient arrival at the desired destination. Data scientists understand this better than most: the necessity of utilizing analytical and systematic approaches to problem-solving.

Download your free copy of the Industrial DataOps Buyers Guide.

The Role of Litmus Edge in Industry 4.0

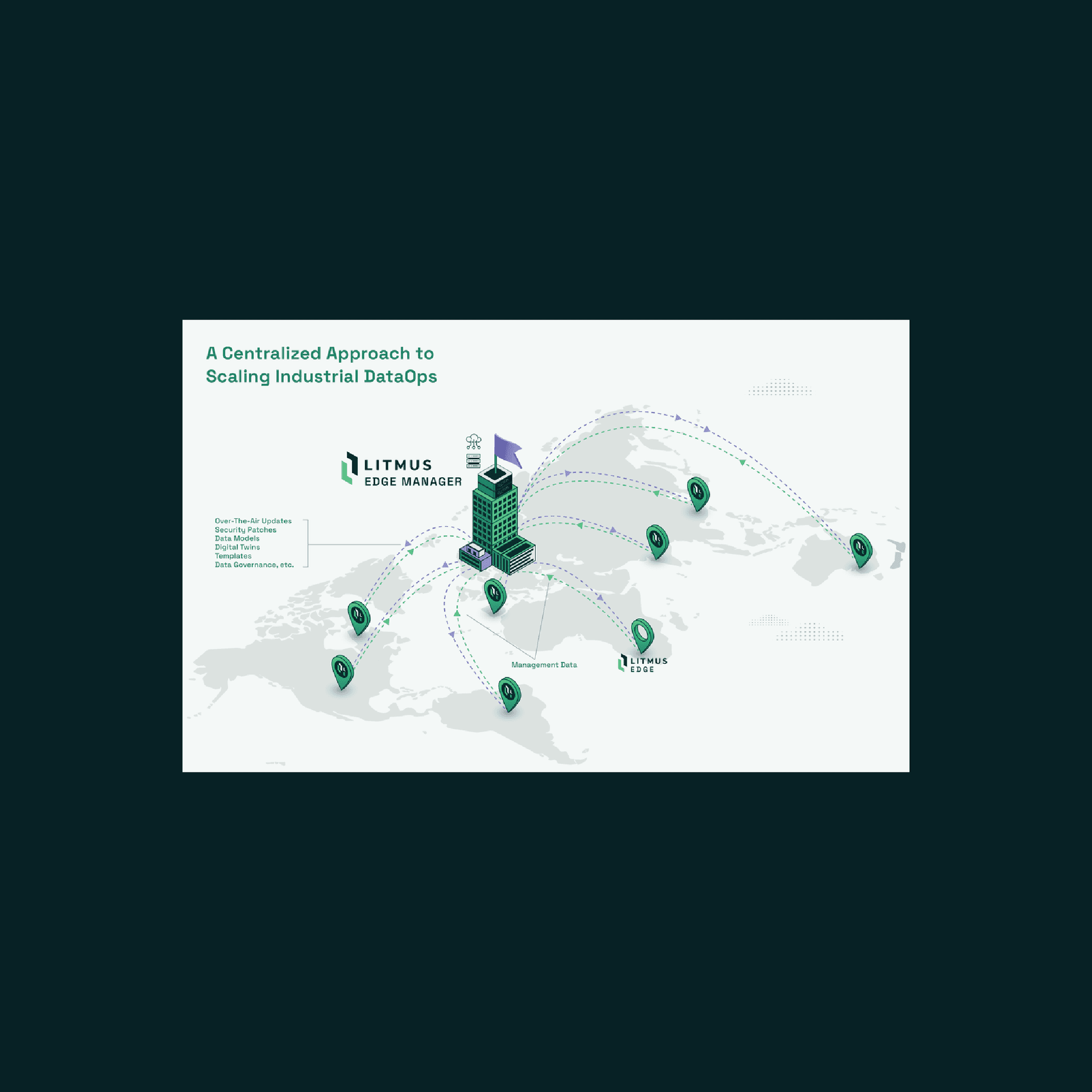

Enter Litmus Edge – a platform that stands at the forefront of facilitating this transformative journey. Litmus Edge is not just another tool in the arsenal; it's a comprehensive solution designed to bridge the widening gap between OT and IT infrastructures. Its power lies in its unified approach, offering an all-encompassing solution that simplifies the integration of disparate technologies and processes.

By enabling real-time data collection, analytics, and integration at the edge, Litmus Edge transforms the vast streams of data generated by industrial operations into actionable insights. This capability turns data into a strategic asset, equipping decision-makers with the information needed to make informed decisions swiftly.

What sets Litmus Edge apart is its ability to offer a panoramic view of operations, connecting the dots across the production landscape. This unified perspective ensures that each technological update or process enhancement is not implemented in isolation but is part of a cohesive strategy aimed at propelling the industry forward towards its 4.0 vision.

Moreover, Litmus Edge streamlines the path to digital transformation by providing a scalable platform that supports the rapid deployment of applications and services. It facilitates the seamless integration of new technologies, such as AI and ML, into the existing infrastructure, thereby ensuring that the journey to Industry 4.0 is not just about technological upgrades but about achieving operational excellence and innovation.

A Collaborative, Systemic Approach

Like the TSP, where the solution is not merely about touching all points but connecting them optimally, implementing Industry 4.0 successfully requires a collaborative, systemic approach that goes beyond just technological integration. It involves aligning business strategies with technological advancements, fostering a culture of innovation, and continuously adapting to new insights and market dynamics.

For data scientists navigating the industrial complexities of today, the Traveling Salesman Problem offers more than just a metaphor. It serves as a strategic framework for applying data science techniques to solve real-world industrial challenges, facilitating a smoother journey towards the realization of Industry 4.0. By choosing the optimal route, not the longest one, we pave the way for more efficient operations and elevated industrial practices.

Get started with Litmus Edge today. Start your free trail.