- DATE:

- AUTHOR:

- Litmus Product Team

Litmus Edge Simplifies Operational KPI Calculations with Off-the-Shelf Capabilities

Litmus Edge provides a wide variety of built-in operational KPIs that can help manufacturing companies in setting realistic targets, improve overall efficiency, quality, and profitability. Check out our extensive documentation to learn how Litmus Edge provides some of these KPIs.

ICYMI: Litmus Edge documentation is now publicly available, without requiring a sign-in.

Asset Online Percentage: The percentage of time that industrial assets are available and operating.

Change of Value: The amount of change in value of a parameter derived as a tag value from an asset over time.

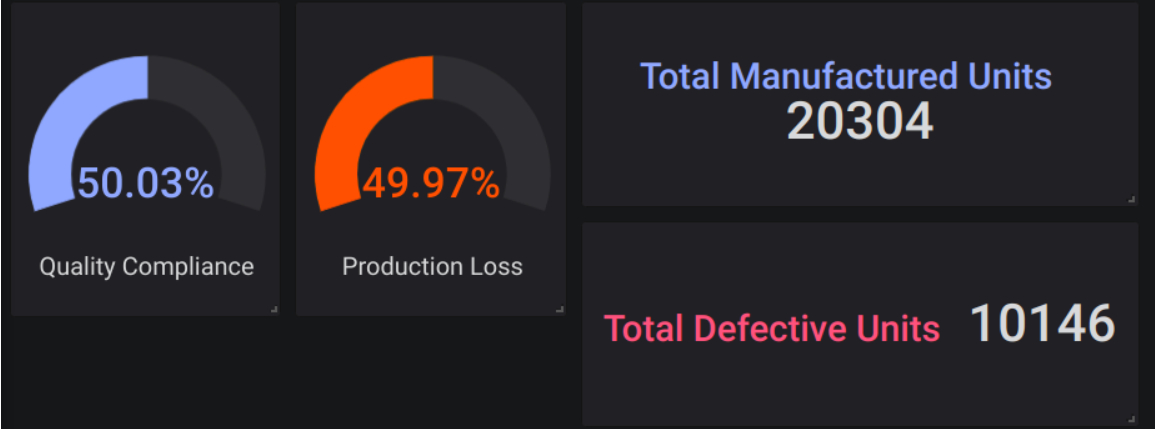

Compliance and Loss: The percentage of semi-finished or finished goods that are compliant with regulations and the amount of loss due to non-compliance.

Maintenance and Failure: The percentage of assets that require maintenance and the number of failures that occur due to maintenance failures.

Online and Offline Percentage: The percentage of time that assets are online and offline.

Production Cycle and Cycle Time Radio (CTR): The average time it takes to produce a product and the ratio of cycle time to target cycle time.

Uptime and Downtime by Value: The amount of time that assets are up and running and the amount of time that they are down and not running, broken down by value.

Example scenario

Asset Online Percentage

Consider a car manufacturing plant tracking the availability of its robots and the efficiency of its assembly process. By identifying and fixing problems early, the plant can improve its output and reduce costs.

For example, the plant noticed that one of its robots was overheating and becoming unavailable more often. By repairing the faulty sensor, the plant can increase the robot's availability and reduce production delays.

Production Cycle and CTR

The plant can also use the KPIs to track the efficiency of its inventory management system. By identifying bottlenecks and implementing new processes, the plant can reduce the time it takes to produce a car. This improvement in efficiency can result in a decrease in production costs and an increase in profitability.

Correlating KPIs

The plant can also use the KPIs to track other areas of its operations, such as energy consumption, waste production, and employee safety. By using data to continuously improve its operations, the plant is becoming more efficient, sustainable, and profitable.

Try Litmus Edge Today

See for yourself how Litmus Edge can help you to take your business to the next level. Sign up for a free 15-days trial at https://central.litmus.io.

Subscribe to https://litmus.io/updates to stay on top of product updates, bug fixes, and upcoming releases.