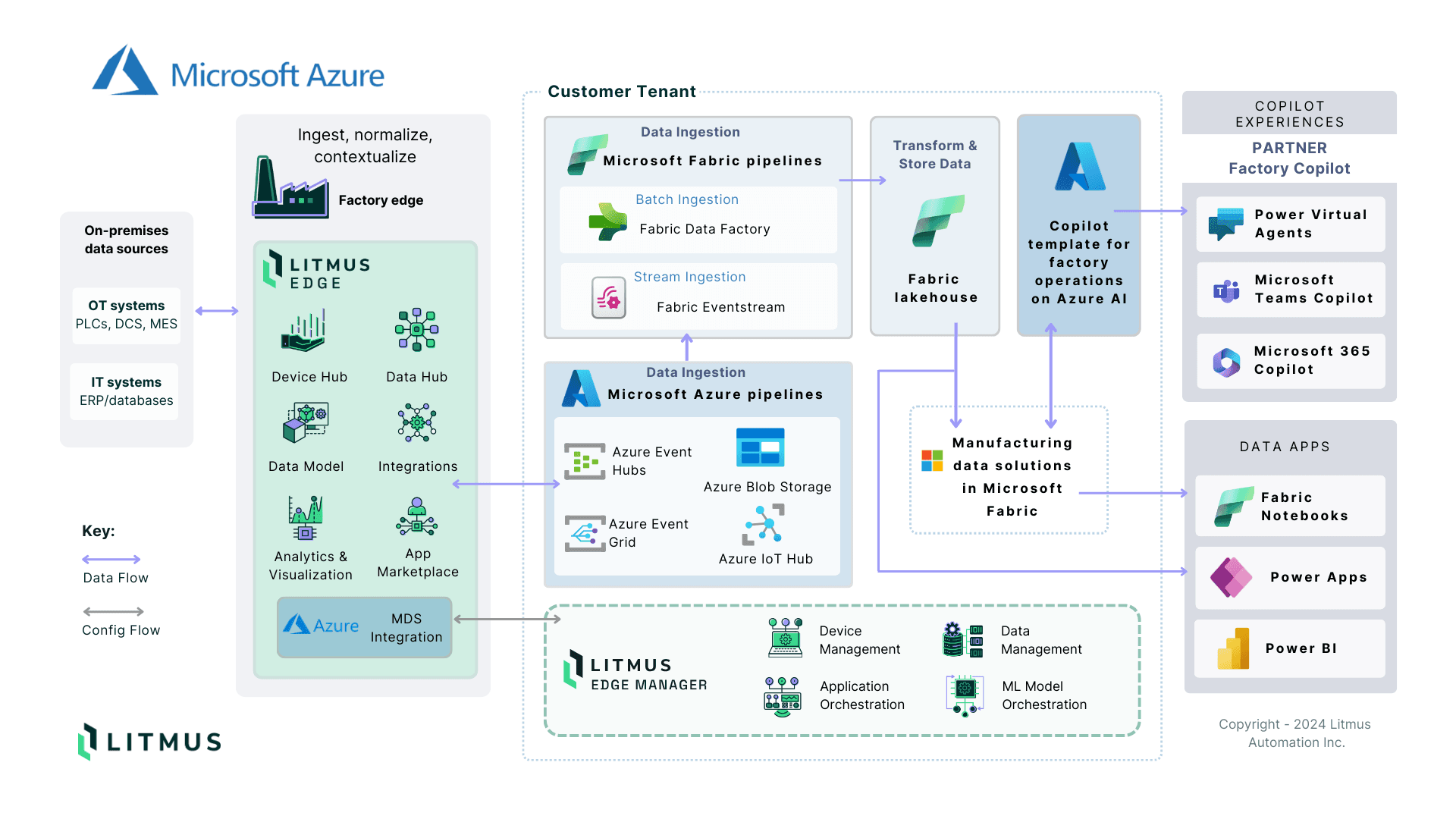

Litmus Edge, a leader in Industrial DataOps collects and normalizes data from any device, providing a real-time gateway to digital transformation. When coupled with Azure Manufacturing Data Solutions, a comprehensive suite designed for data analysis and insights, it creates a robust ecosystem. This ecosystem thrives on the seamless flow of data from the factory floor to cloud-based analytics engines, enabling smarter manufacturing processes.

Solution Accelerator: Send Litmus Edge data to Azure Manufacturing Data Solutions

Leverage the Litmus Solution Accelerator to unlock advanced integration capabilities: bridging Litmus Edge OT data into Microsoft Fabric.

Here’s a detailed step-by-step guide on this integration.

Once transferred, the data from Litmus Edge gets upgraded to a refined layer, enhancing its utility within the Azure Manufacturing Data Solutions Knowledge Graph (MKG). The Microsoft Knowledge Graph, a key component in Azure's Manufacturing Data Solutions (MDS), plays a pivotal role in transforming raw manufacturing data into actionable insights. It's designed to organize and integrate data across various sources, providing a structured and interconnected representation of information. This powerful tool leverages advanced analytics, artificial intelligence (AI), and machine learning (ML) algorithms to extract and derive meaningful patterns and insights from the data. By utilizing the internationally recognized ISA-95 data protocol, MKG offers precision in representing factory data, delivering timely and nuanced insights.

The enriched data lay the groundwork for the Copilot template, which provides a robust suite of tools including domain-specific prompt templates, data grounding skills, and connectors. The template ensures accuracy by validating outputs through post-processing, avoiding the risk of incorrect insights, while Responsible AI (RAI) guardrails maintain the relevance and safety of the responses.

Additionally, partners benefit by customizing and extending these capabilities. They can craft their own prompt templates and connectors or enhance and expand existing data and collaboration applications from Microsoft and other software vendors. This adaptability and enhancement potential make the Litmus Solution Accelerator a pivotal component for gaining valuable understanding of factory operations and ensuring smart, informed decision-making across the enterprise.

For more information on MDS and the Copilot template, explore the Microsoft Cloud for Manufacturing section on Microsoft Learn.

Applications

Below are some compelling applications that harness these integrations:

Predictive maintenance for equipment: Utilize real-time data collection from Litmus Edge and predictive analytics from Azure MDS to forecast equipment failures, thus reducing downtime and maintenance costs.

Quality control optimization: Streamline quality checks by analyzing data from the production line in real-time, thereby improving product quality and reducing waste related to defects.

Supply chain management efficiency: Enhance operations by predicting supply needs and managing inventory more effectively through insights derived from the Manufacturing Knowledge Graph that uses historical and real-time data.

Energy consumption optimization: Optimize energy use by leveraging insights into machine performance and operating conditions, subsequently reducing energy costs and enhancing sustainability efforts.

Custom collaborative robot (Cobot) integration: Develop customized prompt templates and connectors that facilitate seamless interaction between Cobots and human operators, enhancing collaboration and operational efficiency in real-time on the factory floor.

Conclusion

Embark on your integration journey today! New to Litmus? Sign up now on the Litmus Central Portal to begin. Existing Litmus users and partners can easily download the solution directly from the Central Portal. Don't wait—take the first step towards seamless data analysis and enhanced factory insights now!

Reach out to us for more information and to discover how Litmus can unlock and activate your OT data and provide a predictable path to scale your industrial operations.