DISCOVER LITMUS EDGE

Your hub for industrial data.

- Data Connectivity

- Data Collection

- Data Normalization

- Data Contextualization

- Real-Time Data Analysis

- Data Modeling

- Data Integration

Everything you need to make Industry 4.0 a reality in one place ready to go.

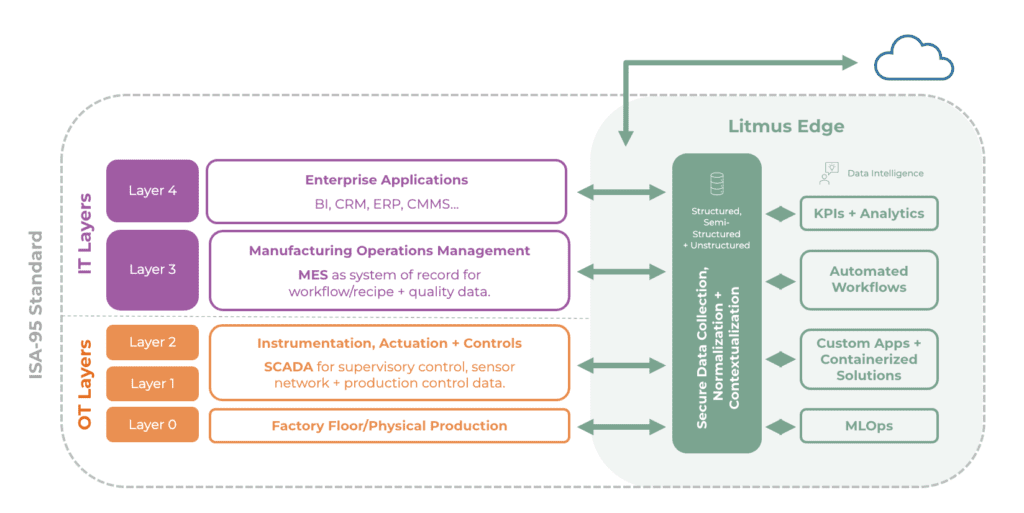

Industrial data infrastructure can be complex. Putting that data to work at scale is a challenge. Doing it securely is even harder. But missing links, OT/IT data silos and lack of visibility across the enterprise isn’t helping anyone.

Whether you’re just getting started, recovering from IIoT horror stories, trying to streamline OEE, looking for a turnkey approach to UNS or want to build us into your wider data strategy, that’s where Litmus Edge comes in with less hassle for OT, IT and everyone.

Maximize Existing Systems

As an additional data layer, Litmus Edge bidirectionally communicates with and makes better use of your existing MES, SCADA, historians and other systems.

Data Modeling + Digital Twins

By optionally adding low/no-code native digital twin and modeling functionality, you can run models and instances within Litmus Edge or Litmus Edge Manager without additional servers and systems.

Centralize Your Data

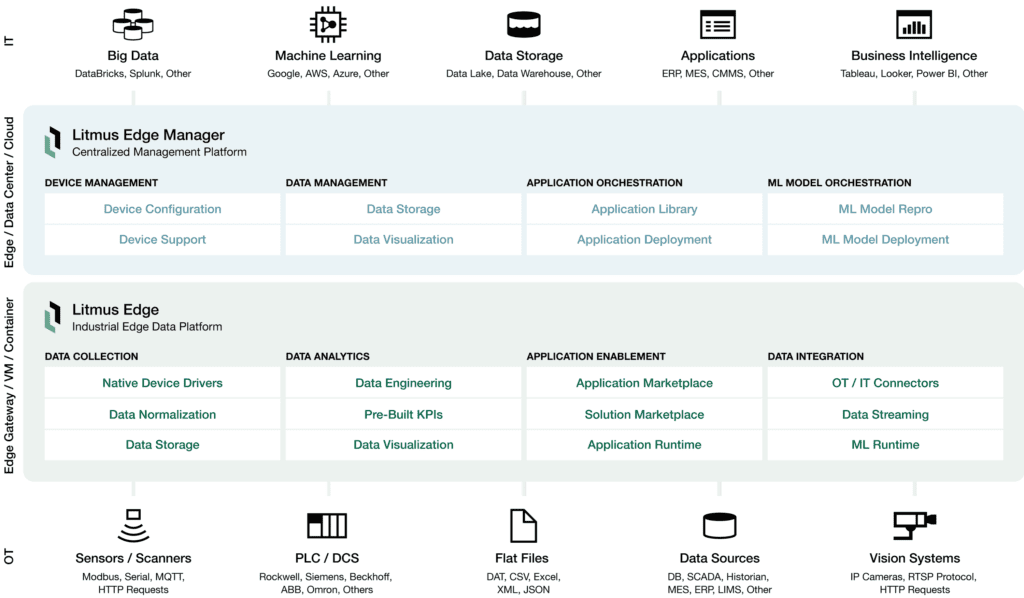

With nearly 275+ prebuilt device drivers, get data from all the sensors, PLCs, flat files, databases and robots across your factory in minutes. If we don’t have a driver you’re looking for, we can develop one rapidly.

Flows, Apps + Templates

We’ve automated repetitive tasks and common use cases with prebuilt KPIs, preloaded applications and vertical-specific solutions available out of the box (or you can add your own).

Cleanse + Contextualize

Litmus Edge normalizes and contextualizes your instream data to make it easier to work with. The structure is consistent, streamlined and optimized for both real-time analytics and storage – at the edge and in the cloud.

Integrate Across the Enterprise

Quickly and securely share data with other edge systems, cloud analytics and enterprise business systems through prebuilt integrations so you’re all working from a single source of truth.

Analyze in Real Time

Move beyond clipboards and whiteboards to take action. Take advantage of prebuilt or custom visualizations, KPI dashboards, alerts and alarms to improve OEE, reduce downtime and optimize throughput nearly immediately.

Scale Securely

Additionally, use Litmus Edge Manager at the edge or in the cloud as a central point of control with centralized data to scale and manage multiple factories and instances of Litmus Edge.

Litmus Edge provides a common language and single source of truth for data-driven decisions.

Explore Litmus Edge low code/no code features and functionality.

What’s included in Litmus Edge and Litmus Edge Manager?

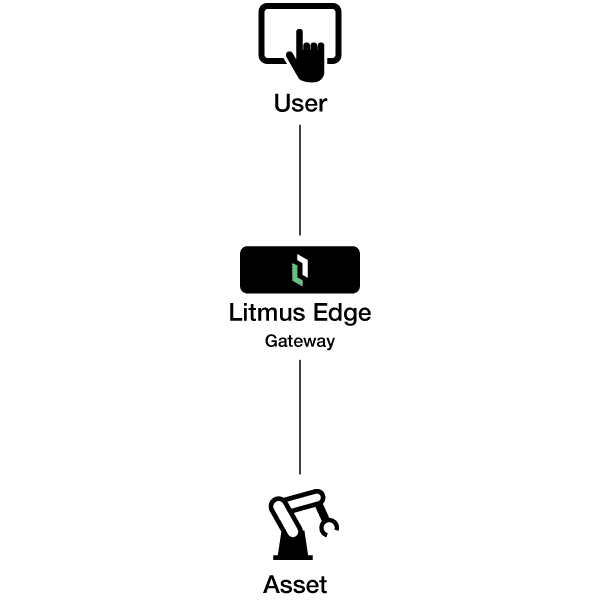

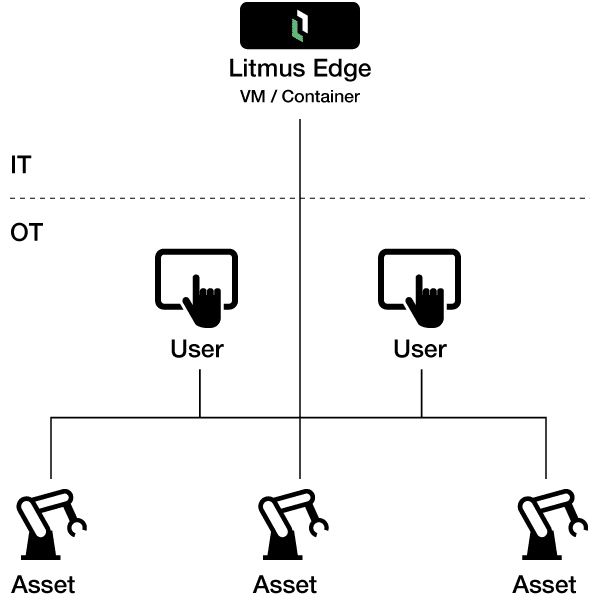

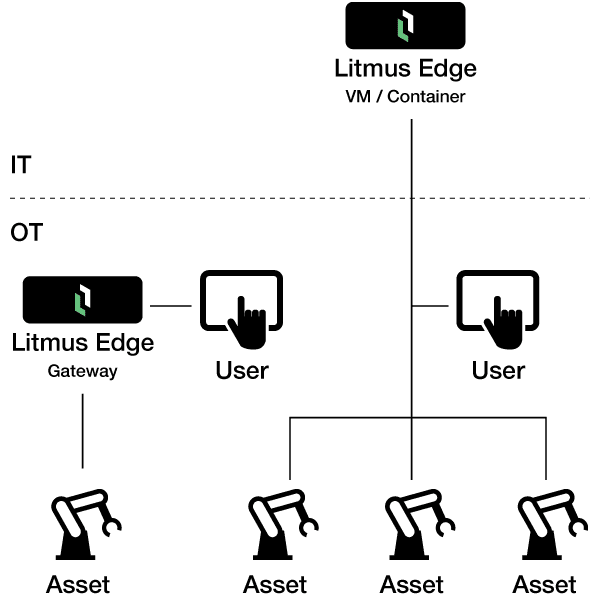

Flexible Deployment

Litmus Edge can be deployed via gateway, virtual machine or container and at the edge, in the cloud or both.

Edge

Litmus Edge can be deployed at the edge, managed by local IT and used to improve operations at the source. Local edge deployment’s ideal for organizations that want a secure way to connect to machines and require a solution that can run outside the enterprise network.

Cloud

Litmus Edge can be deployed in the cloud, managed by enterprise IT and accessed by any data user to improve operations. Cloud deployment is ideal for organizations that need a secure bridge from edge to cloud using the enterprise network to share data across the business.

Hybrid

Litmus Edge can be deployed in a hybrid model – at the edge and in the cloud. Hybrid deployments offer maximum flexibility, enabling local teams to manage edge functions while enterprise IT manages and controls devices, security and infrastructure from the cloud.

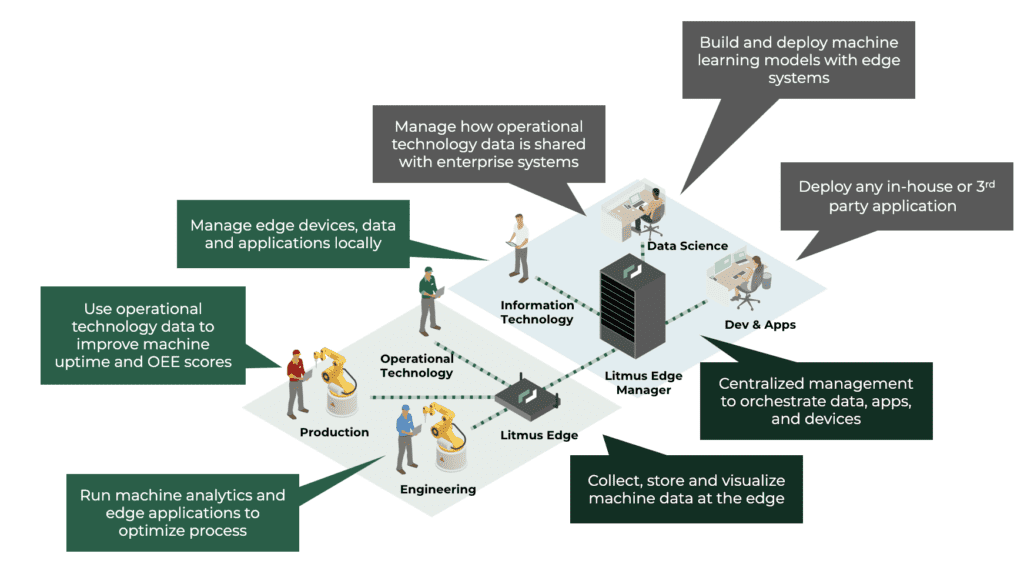

Litmus Edge helps OT, IT and the entire enterprise leverage data to drive growth.

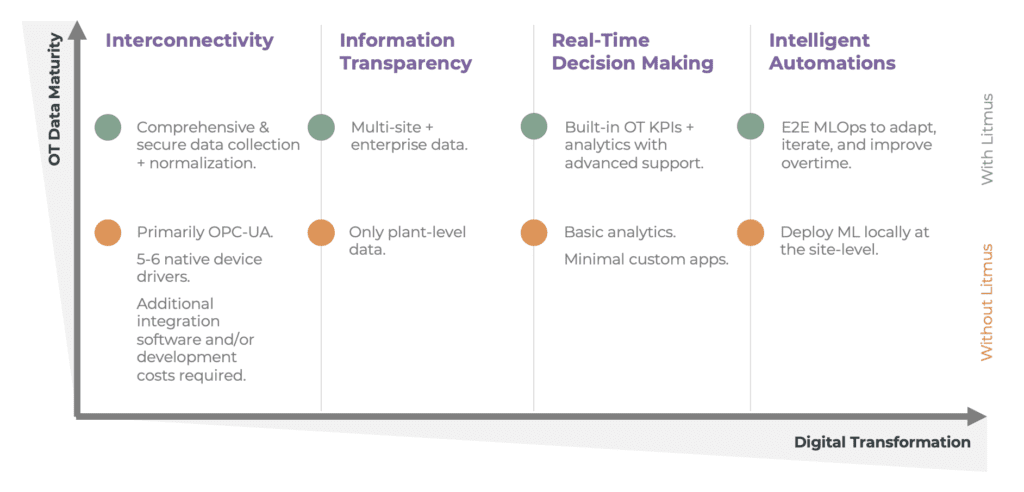

Litmus Edge fosters data maturity and digital transformation for manufacturers.

Want to do more with your data? Let's get started!

Join manufacturers and global brands in over 20 countries around the world who use Litmus everyday.