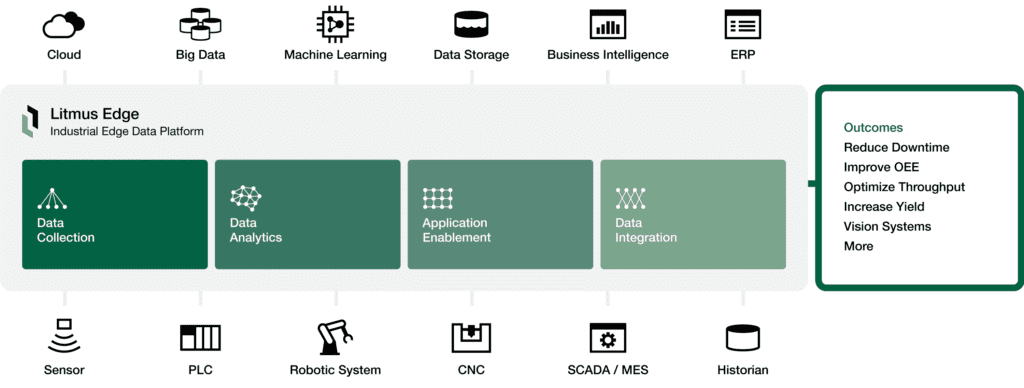

Litmus Edge – デバイスにとらわれないIIoTプラットフォーム

工場やインダストリーデータのハブ

製造現場のデータインフラは複雑で、レガシーシステムやデイジーチェーンとなったソリューションでは解決できません。 データを大規模に活用することは、より一層のチャレンジです。 また、それをセキュアに行うのはさらに難しいのです。 ミッシングリンクをなくし、ヒストリアンとSCADAで処理すべきことはそれらで行い、使いやすく導入が容易なデータプラットフォームで全体の可視性を向上させます。

275 以上の準備済みのドライバー

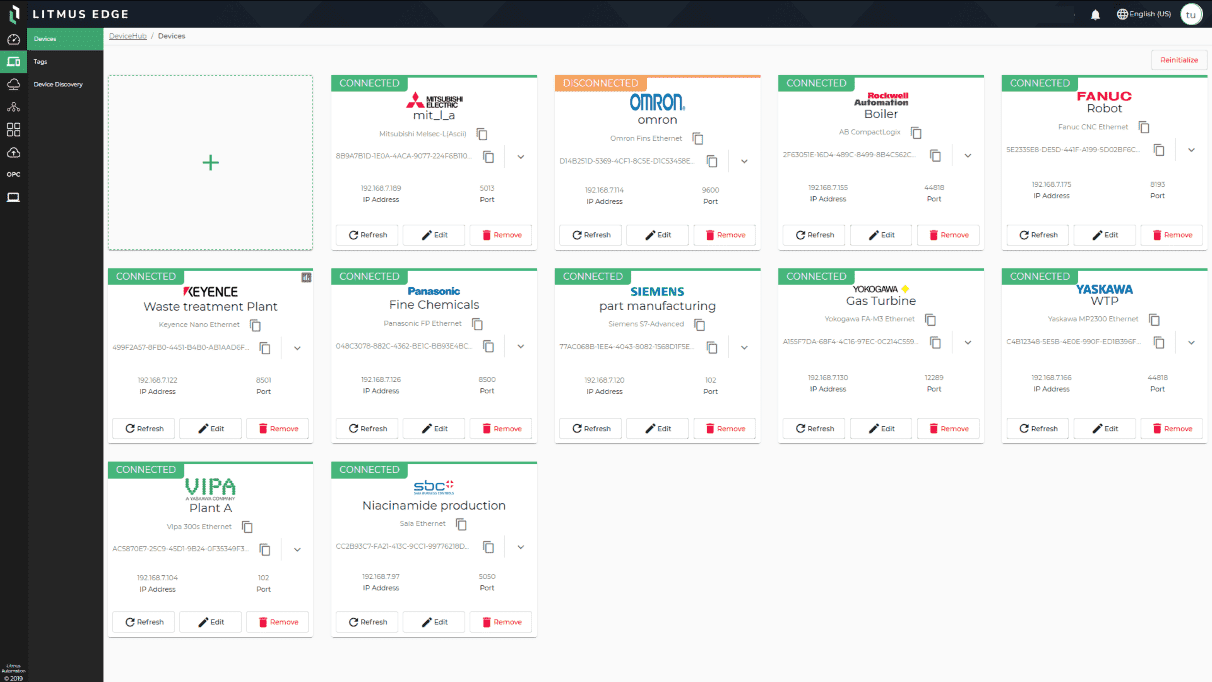

インダストリアルコネクティビティ

PLC、DCS、SCADA、Historian(ヒストリアン)など、すべての設備に数分ですばやく接続できます。 「DeviceHub」の機能を活用し、あらかじめ用意されたドライバー(シリアル、イーサネット、SocketCAN、ファイルベース)でシーメンス、Allen‑Bradley、日立、エマソン、三菱、Modbusなどに接続するだけです。

OTネットワーク上のデバイスを把握

ネットワークのパラメータを事前入力して、ネットワーク上のデバイスを検索しデバイスに接続します。 複数のアプリケーションでデータの再利用を可能にし、より多くのコンテキストを加えるために、作業を進めながらメタデータを追加します。

ネットワーク上のOTシステムの管理

デバイスの静的および動的データを即座に得られます。 デバイスタグを削除し、その最終値、タイムスタンプ、または他のものをチェックします。 たとえば、もしデバイスのログを確認したければ、 デバイスログを有効にするだけで取得できます。

OTネットワークのトラブルシューティング

運用環境にあるデバイスが接続され、アクセス可能かどうかを調べる。 「DeviceHub」の[ユーティリティ]ペインは、何らかの理由でデバイスがポートからアクセスできなくなったり、接続が切れたりした場合、すぐに教えてくれます。 また、ネットワークの問題を簡単にトラブルシュートでき、ネットワークをスキャンするタイミングもコントロールします。

新しい標準化されたインダストリアルデータソース

データの収集と正規化

デバイスや工場のシステムから収集したデータを収集し、正規化し、コンテキスト化します。 履歴分析のために時系列データを保存することができます。 LitmusのDataHubは、企業全体で正規化されたデータへのアクセスを可能にし、組織全体が信頼できる唯一の情報源(SSOT)で作業できるようにします。

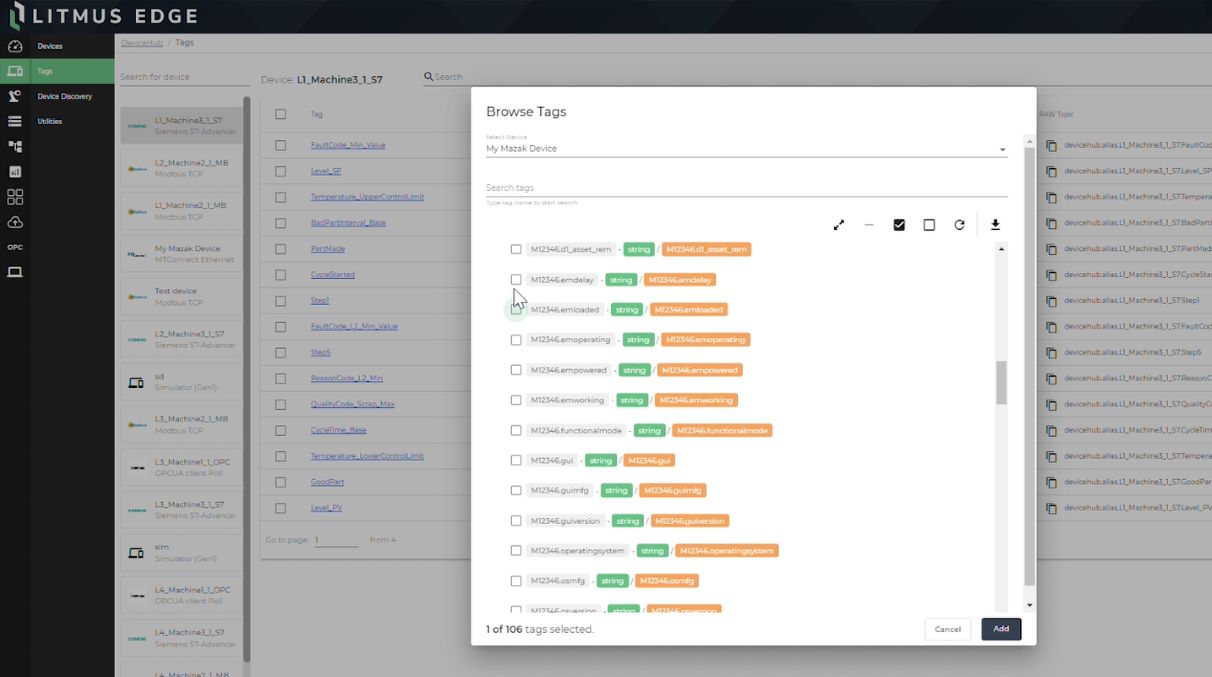

デバイスタグの検索、選択、ダウンロード

デバイスで利用可能なタグを検索、選択、ダウンロードできます。 タグを1つずつ追加したり、CSVファイルを使用して複数のタグをアップロードしたり、あらかじめ定義されたタグのリストを参照したりすることができます。 特定のタグをお探しの場合は、[Server Search]オプションを使って簡単に見つけられます。

独自のデータソースを入手 - 内部または外部

内部または外部の時系列InfluxDBを設定できます。 時系列データベース用のデータソースを変更します。 外部データソースについては、アクセス認証情報も設定できます。 データベースとの接続はテストも監視もでき、わかりやすいメッセージが出されます。

最初から価値あるコンテクストを付与

データ収集開始時から、OTデータに関連性を持たせることができます。 データの検索、使用、再利用に役立つメタデータを追加でき、 デバイス、タグ、特定の拠点の工場フロア、複数の拠点にまたがる各拠点のデバイスなど、さまざまな方法でデータを整理することができます。

自動アラートとKPI

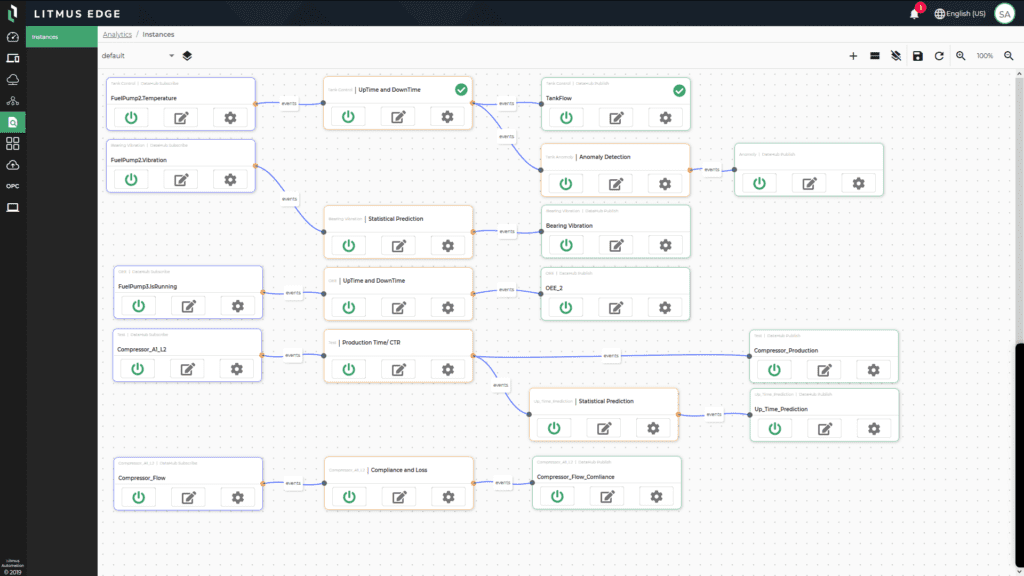

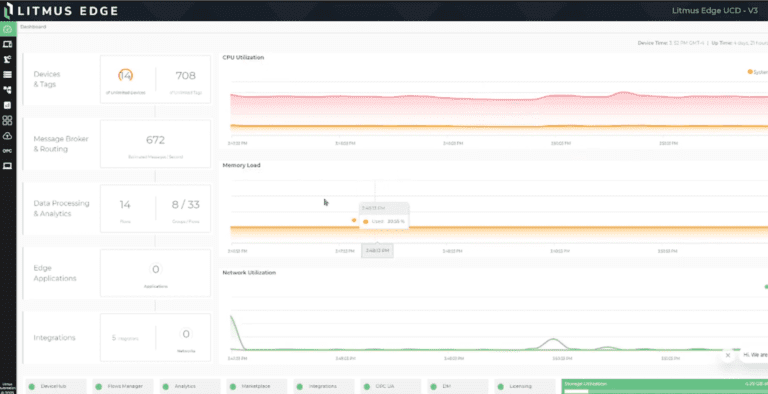

リアルタイム分析

クラウドに送信する前に、エッジで正規化されたデータを処理、分析します。 あらかじめ構成された分析ワークフローをドラッグ&ドロップで使用するか、独自の分析ワークフローを作成することもできます。 OEE、アップタイム、ダウンタイムなどのKPIをノーコードで設定できます。 リアルタイムデータに対して統計分析を実行。その結果をデータに付加し、データにさらにコンテクストを追加します。

分析フローの作成と管理

データを収集、加工処理し、個々の設定にエクスポートします。 エンドツーエンドのフローの作成と管理、ワークフローバグのデバッグ、わかりやすく色分けされたビューでワークフローの情報を表示します。

高度な統計機能でデータを処理

単純なデータ分析以上のことができます。 ガウシアンフィルタ、移動窓平均、異常検知、信号分解など、豊富な統計関数が用意されています。 出力をタグに書き込み、データに実用的なコンテクストを追加します。

事前KPI設定で時間や労力を節約

Litmus既製のKPIを使えば、労力のかかる反復計算は不要になります。 企業全体で標準化するか、または各工場など固有のKPIを作成することもできます。 設備の使用状況、稼働率、生産サイクルタイム、稼働時間と停止時間などをリアルタイムで監視します。

All your apps in one place

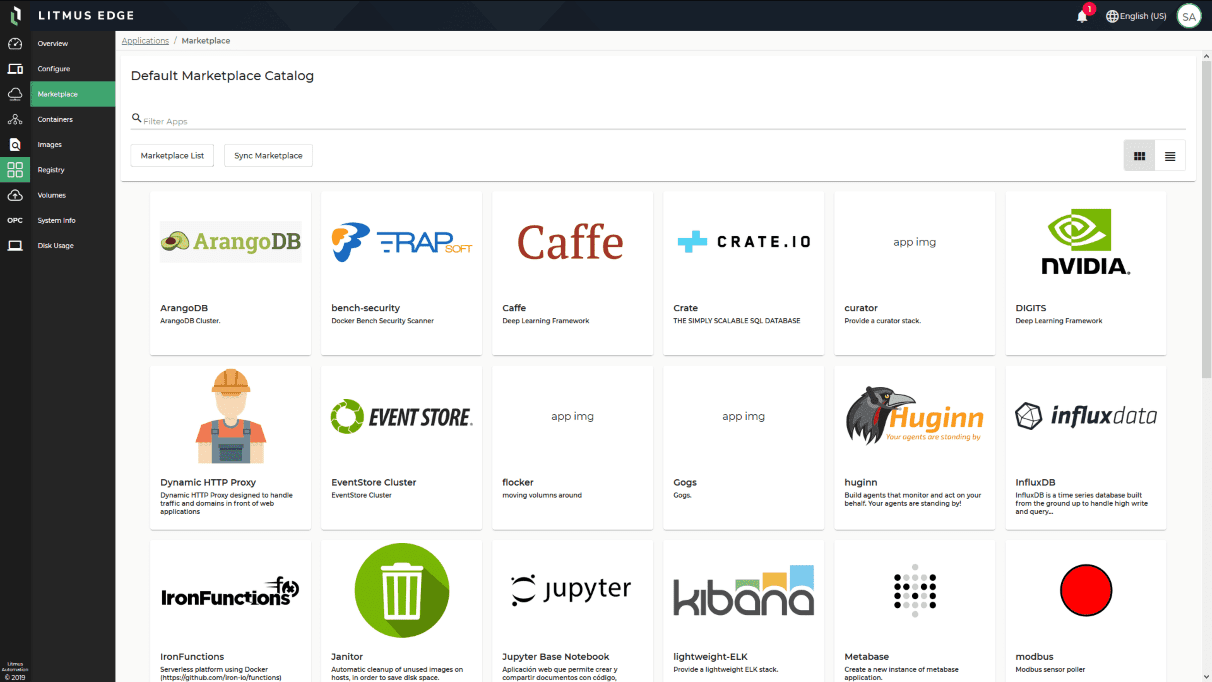

アプリマーケットプレイス

Litmus Edge serves as a platform that allows you to build and deploy various industry IoT apps, and use the processed data in these apps. Over 50 apps, including the Docker registry, are available on this marketplace. You can also create and run custom Docker container applications. Accelerate Industry 4.0 even further with this solution template. This means you can perform application orchestration and lifecycle management on the same platform.

アプリの作成、展開、管理、起動

Elasticsearch、Kx、MongoDB、PostgreSQL、Python、MySQL、Minioなど、幅広いアプリケーションをLitmus Edgeのマーケットプレイスで利用できます。 このマーケットプレイスには、自社のDockerコンテナアプリケーションやサードパーティのアプリケーションを簡単に追加できます。

マーケットプレイスにあるアプリケーションの管理

何か特定のアプリケーションをお探しですか? マーケットプレイスの検索を使って探すことができます。 また、マーケットプレイスカタログに追加して、すべてのLitmusユーザーが利用できるようにすることができます。 そして、自社のアプリを最新のコンフィギュレーションに保ちます。

Dockerコンテナの管理

ITユーザーにとっては、アプリケーションが実行されているのと同じプラットフォームでDockerコンテナ管理することができるようにしています。 たとえば、コンテナの追加と実行、コンテナの起動と停止、コンテナの削除、コンテナのログの表示、コンテナに含まれる設定とポリシーの検査などができます。

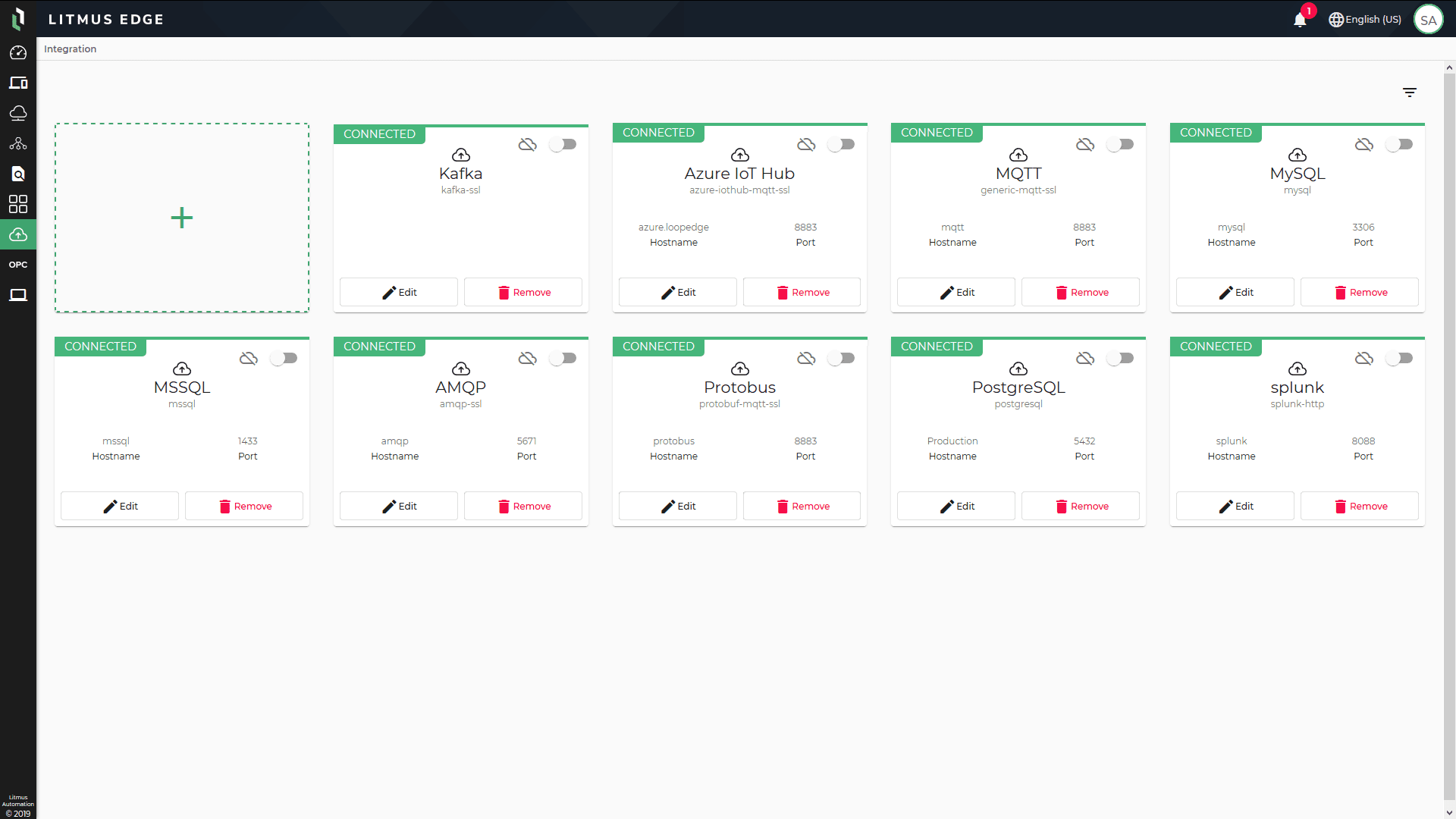

Verified apps and services and REST APIs

データ統合

BIツール、クラウドストレージ、その他のクラウドサービスやアプリケーションに、正規化され、コンテキスト化された加工済みデータを送ります。 同時に、Litmus Edgeへ継続的なフィードバックを得るために、 これらのサービスをREST APIを使ってサブスクライブしてください。

GCP、AWS、Microsoft Azureのコネクタ

わずか数クリックで、加工済みのデータを3大クラウドサービスベンダーすべてに公開、登録することができます。 また、これらのサービスに公開し、登録するデバイスを選択することもできます。

MQTTやAMQP、Kafkaへの接続

MQTTやAMQP、Kafkaなどの外部のメッセージブローカーに接続して送信できます。 一般的なMQTTブローカーに接続する場合でも、AWSやAzure、GCPのメッセージブローカーに接続する場合でも、Litmus Edgeの統合機能でシームレスにデータ交換を行えます。

OTデータをデータベースやBIツールに送る

処理、加工済みの関連性の高いデータをデータベースに送信し、分析できます。 これらのインサイトを定期的に取得し、エッジでリアルタイムにアクションを行います。 生産品質を向上させ、サプライチェーンの問題を軽減し、OTプロセスを制御してタイムトゥーバリューの時間を短縮します。

Machine learning at the edge

機械学習

You can run machine learning models on Litmus Edge. Existing models can be used to predict, classify, and detect anomalies. Get modeled data from the cloud and take real-time actions on data captured from factory devices. Connectors to Cloudera, Microsoft Azure, and others are also available. They enable rapid deployment.

インダストリーデータとは?

Data includes which equipment or system generated the data, when it was generated, what the state was at that time, who operated it, and why the data was generated. Litmus Edge aggregates all this data in one place and can send it to any app, tool, or cloud.

Litmusは製造業での利用向けに設計されています

計画外のダウンタイムを削減し、効率を高め、企業全体でより積極的に行動しましょう。 リアルタイムデータは、サプライチェーンやG2Mチームにより正確なプランニングと予測のためのより多くの洞察を提供することができます。

多くの製造業が、温度、振動、速度などの基本的な設備の各種稼働データを取得できず苦労しています 。 Litmus Edgeは、PLC、DCS、SCADA、Historian、センサーからのすべてのデータを収集、正規化、コンテクスト化し、リアルタイムで各設備のパフォーマンスを把握することができます。

Litmus Edgeやサードパーティアプリを通じて、正規化されコンテクスト化された貴重なデータを機械学習モデルにあて、エッジで新しいモデルを実行し、フィードバックループを完成させます。 Litmusのデジタルツインでは、Litmus自体がデータソースとしても機能するため、モデリングとインスタンスが同じプラットフォームで動作します。

Litmus Edgeが、用意されたKPIでのOEEの計算を劇的に簡素化するために必要な設備データを収集、分析します。 OTおよびITチームは、アップタイム、パフォーマンス、品質を改善するために必要なデータを取得できるLitmuを活用しています。

すべての製造設備からデータを収集・分析し、計画通りの稼働を維持します。 Litmus Edgeプラットフォームは、あらゆる製造設備やデータソースに接続し、データを収集、さらにエッジで分析に加え、それらの価値あるエッジデータをエンタープライズシステムと共有するという複雑な課題の解決を目的に開発されています。 よって、OTチームとITチーム双方とも、設備と工程の稼働時間、パフォーマンス、品質を向上させるリアルタイムのエッジコンピューティングを可能にするLitmusプラットフォームを信頼できるのです。

ステップ・バイ・ステップデモ

- プラットフォームのアーキテクチャを見てみましょう。

- お客様からご質問の多かった機能について、エキスパートが詳しく解説します。

- 用意されたドライバー、ワークフロー、ソリューションを実際に使用し、それがとても容易であることをご体験ください。

ご興味のあるデプロイモデルをご選択ください

エッジのベアメタルハードウェアへの展開

It runs as an OS on bare metal such as embedded x86-64 and ARM (beta) PCs and gateways. Create an air gap between OT equipment and IT systems. This deployment model is ideal if you need:

- Must be connected to factory equipment using a physical interface solution such as CAN, RS232, or RS485

- Need to have computing resources close to equipment for certain highly low-latency or standalone cases

その他のリソース

Litmus customers and partners

廃棄物の削減

クラウドコストの削減

ファミリー経営の食品メーカー

マニュアルによるOEE算出時間を削減

トップ3の航空機エンジンメーカー

迅速な展開

結果を得るためのインダストリーデータプラットフォーム

工場やインダストリー インダストリーIoT スマートマニュファクチャリング インダストリー4.0 インダストリーDataOps インダストリーAI 統合プラットフォームによるプロジェクト

Data collection, analytics at the edge, ML/machine learning at the edge, OT and IT integration, central management – all in one