Case Study

Bottled Water Manufacturer Leverages OT Data to Improve Operations

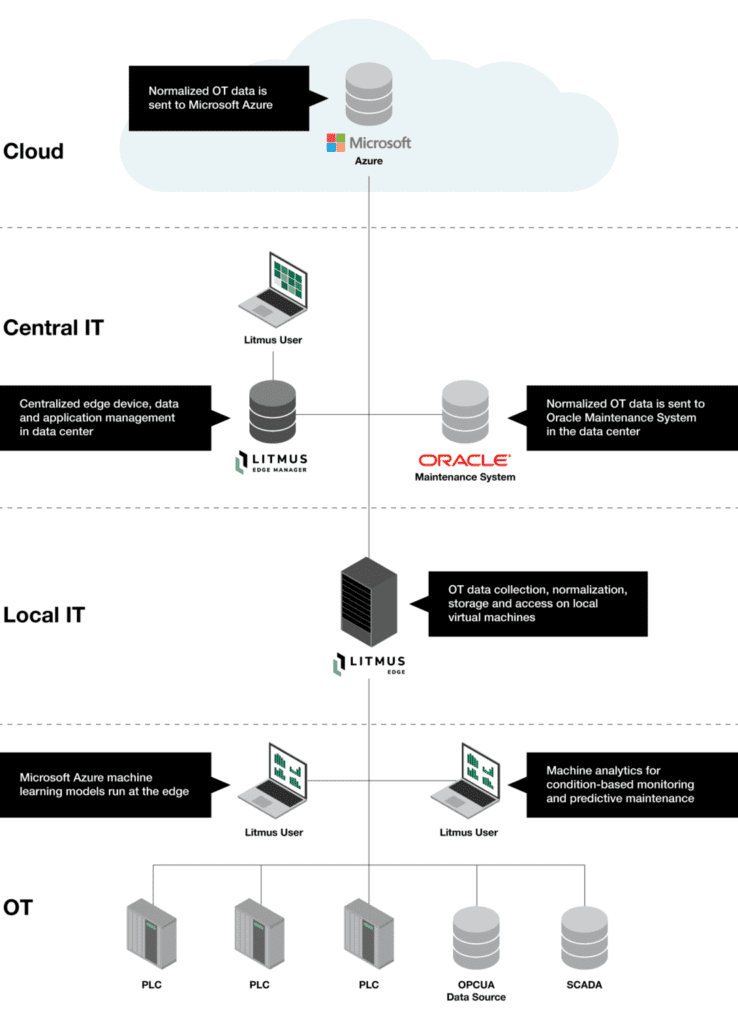

Litmus Edge connected disparate devices, collected, normalized and analyzed the data, and then integrated with Azure IoT Hub for further processing in the cloud. Models are then sent back to Litmus Edge for continuous improvement through the Azure Container or Litmus Edge Manager, a centralized management system for all edge deployments.

Optimized Maintenance

Food & Beverage

Reduced Downtime

3600 Employees

Out-of-the-Box Analytics

40+ Plants

IIoT Success Stories

We’re proud to share challenges, results, projects and initiatives that Litmus Edge and our team have played a role in.

Aerospace Manufacturer Reduces Downtime and Improves OEE

Read More

Food Manufacturer Uses Agritech to Improve Crop Yield

Read More

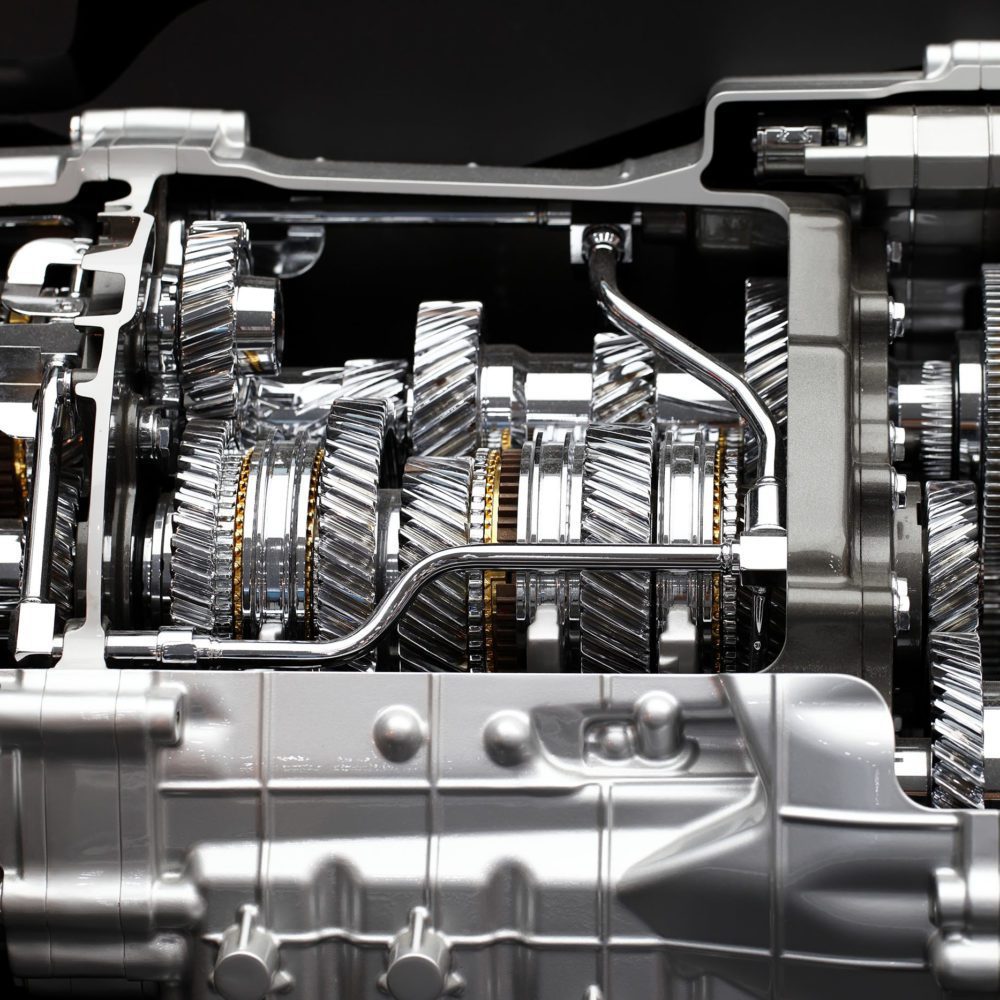

Automotive Supplier Digitizes Manual Workflow

Read More

Industrial Machinery Manufacturer Increases Profits with IIoT

Read More

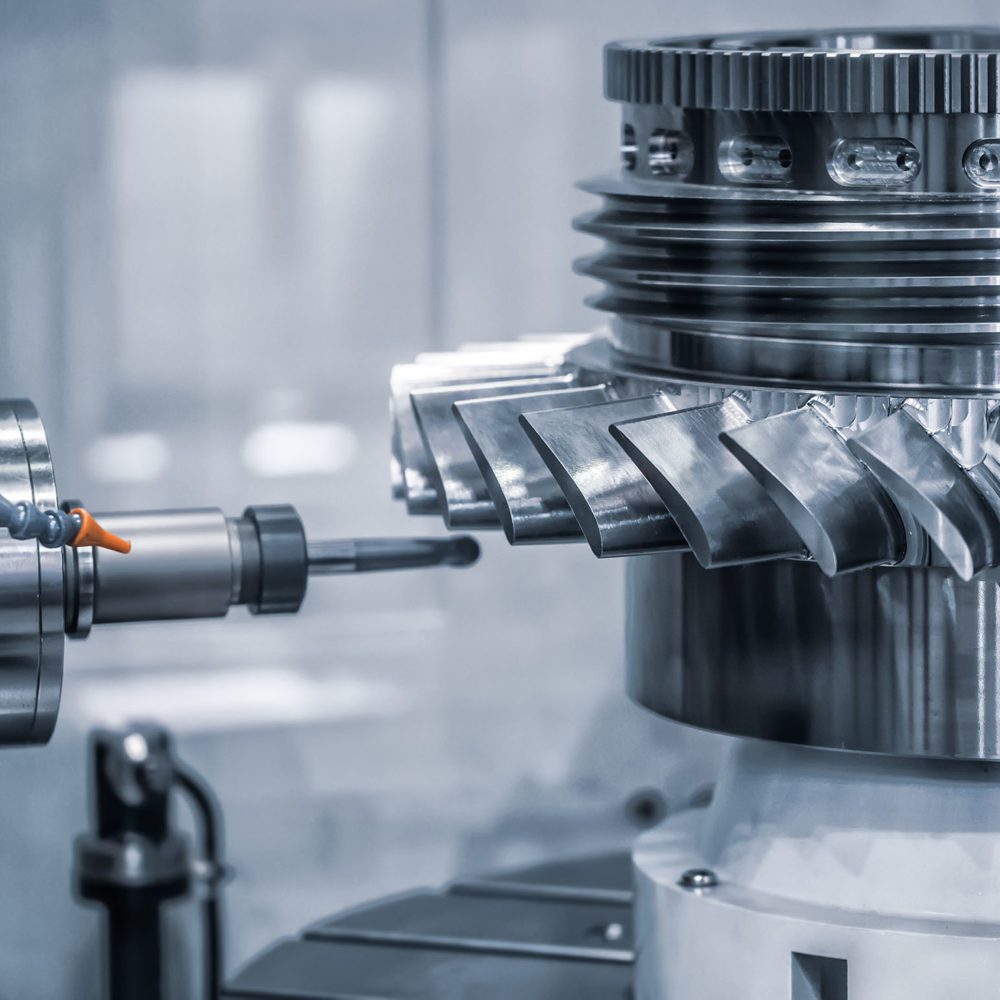

Tool Manufacturer Monitors CNC Machines for Quality Improvement

Read More

Cable Manufacturer Improves Quality and Reduces Manufacturing Costs With IIoT

Read More

Bottled Water Manufacturer Leverages OT Data to Improve Operations

Read More

Mining Company Augments SCADA with IoT Platform to Enable Predictive Maintenance

Read More

Food Manufacturer Achieves Complete Digital Transformation with Litmus

Read More